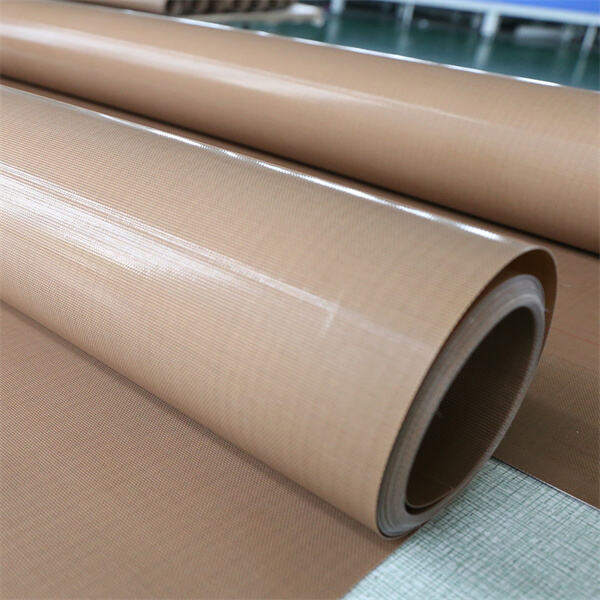

PTFE Woven Fabric, or polytetrafluoroethylene fabric, is an extraordinary material that can stand any kind of mechanical stress and extreme temperatures as found in many industrial applications. So, let's dig down more into the multiple uses of this all-rounder material in manufacturing and industrial processes.

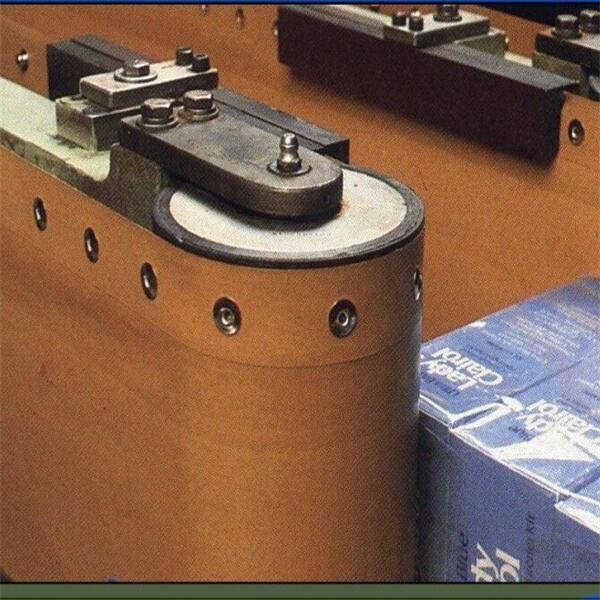

PTFE Woven Fabric is considered as a versatile material that has diverse applications in the industrial sector. One of its most significant uses is in the manufacture of conveyor belts, which play a critical role in ensuring goods continue to traverse seamlessly inside many factories. This is a belt which uses PTFE Woven Fabric for its high strength and long-time life that can also bear extreme temperatures, due to this it enables the environment in manufacturing plants easy running operations.

In addition, PTFE Woven Fabric plays a significant role in the production of insulation jackets that are critical components to regulating temperatures within machinery and equipment. With the power of high and low temperature sustainability, PTFE Woven Fabric offers secure housing against any exposure that can lead to damage-causing improved life of industrial assets.

The durability of PTFE Woven Fabricant helps to bring it in roles where exposure that is continuous severe temperatures poses some sort of problem. PTFE Woven Fabric is used in industries like furnace operations, where it utilises heat-resistant properties of this fabric and fabrics such as PTFE Coated Fiberglass Sheets to maintain performance over long hours within high temperatures usually curtain furnaces which tend not compromise with heavy/fortified sheets but can sustain prolonged exposure at extreme shrink-wrap.

Additionally, PTFE Woven Fabric is an integral component of thermal barrier curtain construction which is essential in providing human and asset protection from high heat sources. The fact that the product can resist extremely hot temperatures and offer high protection shows why it is so important for operational safety while maintaining industrial facilities running with full efficiency.

The PTFE Coated Woven Fabric is extremely versatile and can be used in a wide variety of industrial operations. It is also commonly used in filter bags, which are essential for the removal of impurities from liquids and gases across a wide range of industries. PTFE Woven Fabric is strong and has high-temperature tolerance which make this fabric perfect for filter bags to go through the purification process without getting damage.

Moreover, PTFE Woven Fabric is used to manufacture release sheets that keep things from having difficulty with the surfaces of machinery. These non-stick fabrics fortified using the inimitable strength of the fabric are a great way to reduce wear and tear on your industrial processes, improving efficiency as well as productivity.

Exploiting the Chemical Inertia of PTFE Woven Fabric to Deliver Exceptional Performance

PTFE Woven Fabric is also resistant to most of the chemical that gives it a long life in those applications where there exposure to variety of chemicals. This fabric is used in the construction of chemical storage tanks, which are an easy and secure way to store chemicals either individually or mixtures provide a structure that maintains integrity.

Not only this it significantly help in avoiding machine leaks, as using PTFE Woven Fabric in the manufacturing of gaskets. Resistant to chemicals and built in heavy duty manner, so helps prevent leakage which means it keep your industrial home operational safer & leak-free.

PTFE Woven Fabric supports numerous important tasks in industrial processes thereby providing improved performance and longevity. Whether for their use in conveyor belting or insulation jacket manufacturing, this fabric will add convenience to operations and at the same time provide longevity of asset protection.

While one of the many benefits that PTFE Woven Fabric lends to industrial use is obvious -increased safety measures-, touting its value in terms of manufacturing and industry precision has underscored the practical purposes this economical material serves as a stapler today.

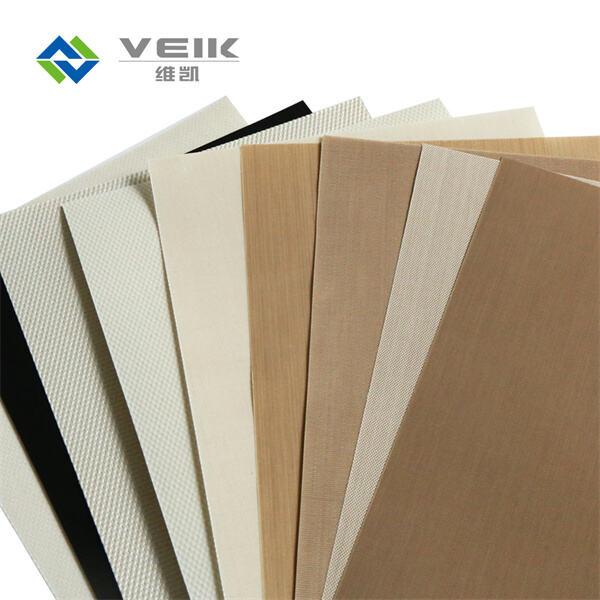

Based on the principles of taking roots in the lands and looking to the global markets, our products have been sold to more than 60 countries in Europe, America, ptfe woven fabric, Middle East, Asia Pacific, etc., which are widely used in foods processing industry, constructions industry, automobile industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshades curtain and other fields.

Our company has been ptfe woven fabric Veik and creating national brands. Our company puts quality first. We have our products cleared SGS, the national glass fiber products inspection and supervisions, as well as the national fireproof material controls and inspection. Veik, is a Jiangsu high-tech company is located in the provinces of Jiangsu.

We've had ptfe woven fabric, and we have 10 dip production lines as well as 2 coating production lines, and five PTFE architectural membrane production lines. We have imported more than 10 sets of horizontal and vertical drying equipment, Germany Karl Mayer high-speed warping machine that is automated and Dornier wide-width taper loom. Our annual production capacity is 1 million square metres.

In the future, VEIK will continue to maintain its ptfe woven fabric, concentration professionalism, and integrity. Concentrates on the needs of customers and continuously improves our quality, and provide superior service.