While many in the packaging industry may overlook Teflon tape as just another small item, it is a very important accessory when dealing with heat sealers. This particular fluoropolymer-coated tape is famous for being stick-resistant and heat resistant. It is now a crucial part in making certain sealing procedures across numerous sectors operate successfully. From sealing food packages to pharmaceutical products, the use of Teflon tape not only guarantees secure seals but also assists with maintaining the freshness and safety of your goods. As we dig into how it is used, you'll start to learn why this small addition means a lot in your system and choosing the right one can really help boost the power of your heat sealer.

Teflon tape stops the heat mesh on a sealer from adhering and curdling to your packaging. This is what really matters about Teflon tape, after all. The bag sealer is used to make sure that the items are safe in containers and no imperfection of seals will occur, any contamination by products or even damage to the sealer itself. The sealer works in a smooth manner by making use of the non-stick property if Teflon which means one need not maintain it often and cleaning is also done less frequently or having to change parts quite often. It also functions as a guard against heat transfer meaning the parts of the sealers are not subjected to too much abrasion due to constant use.

Teflon tape does not only protect sticking. It resists high temperature which is why heat can penetrate it evenly when used to seal so that seals become strong and will not leak or damage easy. This consistency is imperative for industries which rely on the packaging material to ensure that product quality and shelf life are not compromised as a result of poor package integrity. Teflon tape, additionally, can keep closed packages looking clean through keeping scorch marks or discoloration from warm surfaces.

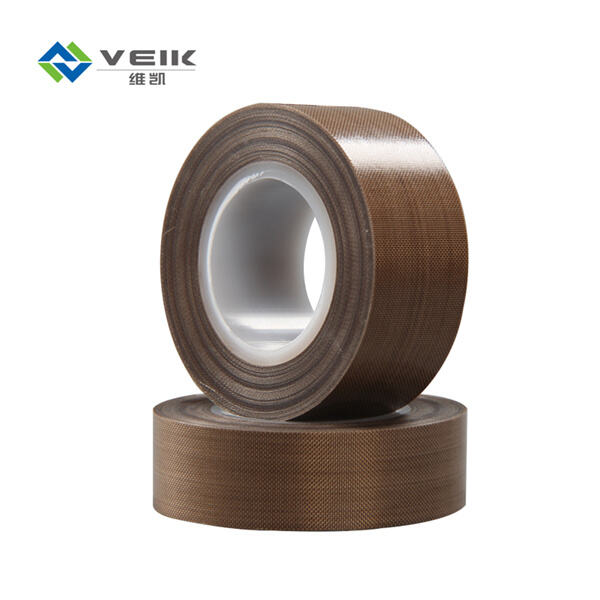

However, it is essential to remember that not all teflon tapes are equal in quality and efficacy. Better Teflon tape is often more robust and temperature-resistant, which makes it last longer because of sealing purposes. It instead needs to be adequately thin so that it is bendable yet strong enough to go around the sealer's heating element with ease. In addition, premium tapes are less likely to shed particles as may some lower-grade adhesive residues which ensuring that your product remains contamination free; a vital consideration for food and medical packaging.

Due to a variety of factors involved, it is crucial before anything what tape should you select. First, you may need to find out what temperature your heat sealer operates at and, Secondly that the tape won't break down). Measure the width and thickness suitable for your model of a sealer. It also depends on the tape being used (how often it is being run and what sort of material are you sealing- polyethylene, polypropylene for example), which will determine how durable or non-stick your application needs to be. Similarly, safety certifications can be graded as simple or comprehensive - e.g., depending on the type of printing and application you will need FDA approval if it relates to food / medical packaging) so ensure that your prints meet their strict standards.

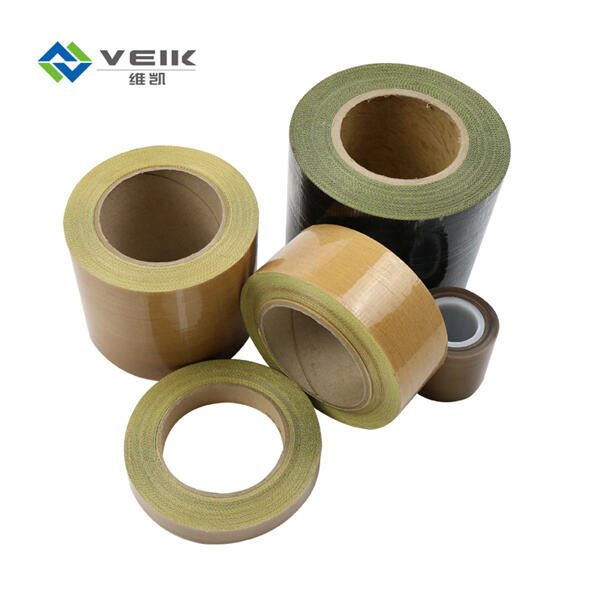

Our company has been dedicated to the idea of building century Veik and building national brands. Our company puts teflon tape for heat sealer. Our products have that have passed SGS, the national glass fiber product inspection and supervision, as well as the national fireproof material inspection and supervision. Veik is a high-tech company in Jiangsu province.

The company's business philosophy will stays better quality and teflon tape for heat sealer, professionalism, integrity for the foreseeable future. Be attentive to the needs of the customers Pay attention to the constant improvements of our own performances we are committed to providing our customers better services, providing more efficient energy, safer, more environmentally green long-term values to customers.

Based the teflon tape for heat sealer in land and looking to the global markets, our products have been sold more than 60 countries in Europe, America, Oceania, Middle East, Asia Pacific, etc., which are widely used food processing industry, constructions industry, automobile industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshades curtain and other fields.

Our company has been teflon tape for heat sealer. We have a total of 10 dipping lines, two coating lines and 5 PTFE architectural elastomer production lines. We have imported over 10 sets of vertical and horizontal drying equipment, Germany Karl Mayer high-speed automatic warping machine and Dornier taper loom with wide width. Our annual production capacity is 1 million square meters.

As we mentioned earlier, one of the most important roles Teflon tape plays in heat sealing is helping to form airtight seals. Teflon tape can be very useful to create durable and reliably water-tight seals, especially in industries where maintaining freshness is important and preventing contamination at all costs. This is especially important for perishable products, where a small break in the seal can cause material to spoil or decrease in quality. Elimination of the risk adhesive failures ensures a longer shelf life, minimum waste and increased consumer confidence that package contents are both safe to consume and fresh.

So it may not be as big and showy as the other parts of a heat sealer, but that little Teflon tape is also one of its most important components. The variety of advantages it provides, from improving operational efficiency & product quality to making the process meet stringent industry standards equally points at its necessity in contemporary packaging processes By using a suitable adhesive selector, and making sure that the Teflon tape is accurately placed - helps to improve flow of hot air in heat sealer so it adheres appropriately on to the filled bag helping you protect your product integrity, freshness & consumer happiness as well.