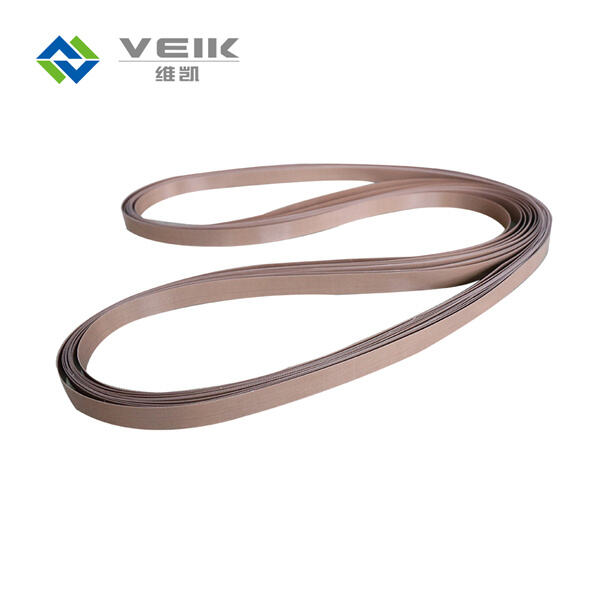

Did you ever wonder the steps it took to make your everyday wear clothes? One of the essential machines in clothing production is a fusing machine. From attaching linings to main fabrics together, this ingenious tool used in the industry helps keep clothes durable as well as stylish. Yet, what they may not know is that a critical player for the machine also exists — The fusing machine belt. However, this oft-overlookedbelt is what aids in the making of clothes with better quality (and more speed).

However we should also mention that the fusing machine belts are not consistent across all offerings Certain belts are prone to slipping or breaking, meaning you might experience problems in the production process. Such interruptions are frustrating and, more importantly for the person running a machine, they can be extremely expensive. It therefore highlights the importance of using superior quality fusing machine belts that are cost-effective and can be used for longer periods to assure uninterrupted operations at maximum efficiencies.

The world of machine tapes and fuser belts is not excluded as technology continues to evolve very fast. New belt technology advancements have been produced with the consideration of maximizing productivity while using fusing machines. For example, the introduction of PTFE coated belting Conveyors has redefined our industry. A specialized belt built with a different type of coating, virtually making the problem of sticking and slipping void offering long lasting usage compared to standard belts. One interesting improvement is that they use Kevlar fusing machine belt, which I must say it very durable and can last a long time as its heat resistance property will keep it from melting. Being strong in nature the Kevlar belt is competent enough to perform stably even under high loads and speeds.

If you have ever tried fusing machine belts, you know that one of the many problems is belt slippage: this can stop a machine from functioning and inflict damage. To alleviate this problem, the industry created heavy duty fusing machine belts that were designed to solve it. In this way, users are spared from the implications of heat and overuse by these belts since they boast almost indestructible durability thanks to heavy-duty materials like Kevlar an fiberglass.

There is no doubt that producing clothes has huge importance regarding quality. More than design, consumers want timeless fashion. You cannot meet those standards if you are not using machine belts of a professional grade - especially during the fusing process. Made of the highest quality PTFE and Kevlar, these premium belts are made for individual types of fusing machines. Using these specific belts that are crafted to impeccable precision, companies can ensure their fabric gets the best fusing quality needed for perfect garment production.

Finally, fusion machine belts are the critical bridge that maintains one of the most complex endsconfronting points in clothing manufacture. These belts play a vital role in joining fabrics and thereby enhance the ability of the end garments. Choose the right fusing machine belt taking into account parameters;efficiency, longevity and quality should be your priority for smooth functioning. Our fusing machine belts are offered in various specifications, meeting the requirements of a large scope. Whether you need heavy duty belts or best-in-class bonding capabilities our wide selection has what you need. Go for quality — select one of our fusing machine belts and take your clothing production to the demanding level!

Our company has been dedicated to the idea of building century Veik and building national brands. Our company puts Fusing Machine Belts. Our products have that have passed SGS, the national glass fiber product inspection and supervision, as well as the national fireproof material inspection and supervision. Veik is a high-tech company in Jiangsu province.

VEIK's business philosophy will remains better quality and concentration on professionalism, reliability, and Fusing Machine Belts. Pay attention to customers requirements, improve our quality continuously and offer superior customer services.

Based on Fusing Machine Belts and looking to global markets, our products have been sold to more than 60 countries in Europe, America, Oceania, Middle East, Asia Pacific, etc., which widely used in foods processing industry, constructions industry, automobile industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshade curtains and other fields.

We have a Fusing Machine Belts, and have 10 dip productions lines, 2 coating production lines and 5 PTFE architectural membrane productions lines. There are more than 10 sets of horizontal and vertical drying equipment for coatings, Germany Karl Mayer automatic high-speed warping machines Dornier wide-width, rapier looms and other imported equipment. Annual productions capacity is 1 million square meters.