Short of putting on kneepads, Kevlar is superhero stuff in fabric-world. This strong and durable to ensure that people are safe when they might be in danger. Yes, I felt like the only thing missing was a vest and helmet made of Kevlar to complete the image. These items are critically needed by police officers and soldiers who have to be safe so as to perform their tasks. Kevlar is even used to make gloves that protect people from sharp things like knives or glass!

How Kevlar is Made, Explained It is composed of thousands and thousands of small fibers that are extremely tiny yet very powerful. The fibers in it are laid down on a diagonal crisscross pattern so that bullets and dangerous tools cannot penetrate. As a fly is held by the strong webbing of its silk, Kevlar can trap and hold potentially lethal objects away from people.

Kevlar for More than Protection It was also used in creating sports equipment such as skis, snowboards and hockey sticks. Well this is because Kevlar, In a nut shell it's Light Weight Flexible and strong… Like we said Perfect for sports. Athletes are able to use Kevlar when they compete for a few reasons: They need equipment that allows them to perform at their best, and being lightweight helps an athlete move without any additional weight strapped on.

It is also used to make other very tough things such as car tyres,cables for lifting heavy objects, ropes in climbing and parts on airplanes. By utilizing Kevlar in these items, it extends their life and helps them avoid damage from consistent wear. What this means is that items made with Kevlar can withstand challenging environments and still work effectively over a long period.

Kevlar fabric manufacturing process The Kevlar fabrics are created using these special chemicals known as polymers. The molecules are melted, then extruded out of a small device with tiny holes. The process involves spinning long fibers into yarn, then weaving them together to form a durable fabric that allows for elasticity.

One of the big deal elements with respect to Kevlar is that it has been a move player in enabling technology use over 30 years. This leads to the development of better protective gear and sports equipment, so that athletes can stay safe while enjoying their passion. It likewise serves to make preferable mechanical items, implying that regular things like autos and planes are more secure and stronger.

The uses for Kevlar will only grow more exciting as technology continues to advance Now researchers work to make new materials which are much stiffer and durable enough for a range of different uses. The uses of Kevlar are endless - who knows where it might pop up next? One day it might be used in space missions or deep underwater explorations!

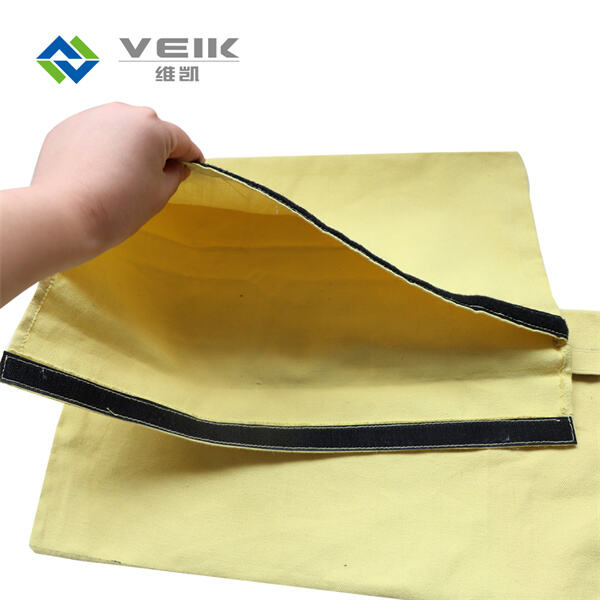

Our company has been determined to follow the philosophy of building century Veik and kevlar fabric. Our company prioritizes quality over all else. Our products have cleared SGS which is the national inspection of glass fiber products and supervision, and the national fireproof material control and inspection. Veik is a hi-tech enterprise located in Jiangsu province.

VEIK's business philosophy will remains better quality and concentration on professionalism, reliability, and kevlar fabric. Pay attention to customers requirements, improve our quality continuously and offer superior customer services.

Based on the principles of taking roots in the land and looking to the global markets, our products have been sold to more than 60 countries in Europe, America, Oceania, kevlar fabric, Asia Pacific, etc., which are widely used in food processing industry, constructions industry, automobile industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshade curtains and other fields.

Our company has been kevlar fabric. We have a total of 10 dipping lines, two coating lines and 5 PTFE architectural elastomer production lines. We have imported over 10 sets of vertical and horizontal drying equipment, Germany Karl Mayer high-speed automatic warping machine and Dornier taper loom with wide width. Our annual production capacity is 1 million square meters.