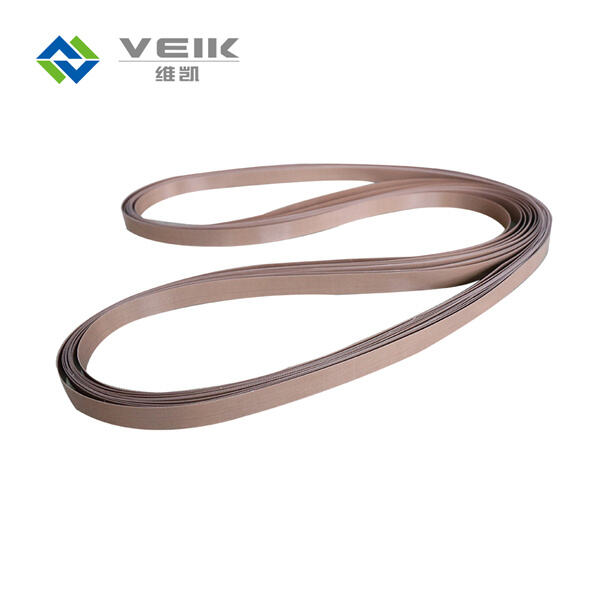

This article is an exploration of the PTFE coated belts - a particular belting variant used across different industries in manufacturing. These belts come with a variety of benefits - from their superior toughness in the toughest industrial environments to being revolutionary for food processing. Keep reading to learn more about the advantages of this belt and why they are critical in high-temperature applications, as well as details on relatively new technology that is a significant component for conveyor systems across industries.

PTFE coated belts are ground-breaking in the manufacturing sector with its great opposition to chemicals, heat and abrasion which makes them a incredible option for immoderate industrial regions wherein durability is vital. It has an extraordinarily low coefficient of friction that provides superior "glide" across nearly any surfaces and also meets specified operating performance requirements.

Another important feature of PTFE coated belts is their non stick properties. Again, the lack of tack is a benefit for many manufacturing processes because no materials can stick to these parts. It is also highly cleanable and low-maintenance to improve the life of a belt conveying system while saving costs.

PTFE Coated Belts Entering The Era Of Food Industry 2.

PTFE coated belts are common and beneficial in the food sector with high chemical resistance, as well as a nice heat-resistant capacity. Their versatility enables them to be used across a range of processes, meaning you know the product will be safe and secure.

Perhaps the most important of all benefits that come from using PTFE coated belts in food, is its nontoxic property. The belts are food-grade and free from toxic chemicals that could cause food to be contaminated without a doubt, always following the strictest rules of safety for human consumption. Not only this but they also prove to be a useful tool in frying and baking due to their clean easy non-stick aspect which is important when it comes to hygiene.

PTFE coated belts are designed to handle even the highest temperatures (up to 500°F or 260°C), and can be used in a wide variety of processes including curing ovens at high heat settings, industrial dryers,tasters for dried fruit, sublimation interfaces sealing machines and more! They are also essential in the manufacture of heat application processes such as plastic wares and electronic kits.

In this case, the efficiency of belts having a layer of PTFE is enhanced by new technologies in PTFE coating. Technological developments such as the more advanced coating formulations offer higher chemical and abrasion resistance, to even finer belt manufacturing. These improvements are not only more accurate, but they last in efficiency for decades.

Advantages of PTFE Coated Belts in Conveyor Systems for Different Industries

PTFE coated belts are ideal for virtually every type of conveyor system across a wide range of industries, thanks to the benefits they provide. LowCoF ( Coefficient of Friction) helpful for low rolling resistance like in conveyor transport systems. In addition, products can pass easily from belt point A to B without staying along the way due to PTFE coated layer that used in production of it and this is may cause a problem with other belts.

In short, PTFE coated belts are a special permium gift the manufacturing plant from waterotec These properties are what make them priceless in harsh industrial conditions that may be hostile to chemicals or heat. Specially,for food sector where it is required to have safe and easy.... The high-temperature transfer belts of the series have been specially developed and, as a small number sold, available for special applications at very heavy temperatures. Additionally, with their motor selection service they play a huge role in various industries utilizing conveyor systems.

The VEIK business model will continue to be better quality and concentration on professionalism, ptfe coated belt, and concentration for the foreseeable future. Concentrates on the needs of customers Pay attentions to the constant improvement of our own performances, committed to providing customers better services, providing more efficient energy safe, environmentally green long-term value to customers.

Based on principles of taking roots in the land and looking to global markets, our products ptfe coated belt in Europe, America, Oceania, Middle East, Asia Pacific, etc., which widely used in foods processing industry, construction industry, automobiles industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshade curtains and other fields.

Our company has been in the business for many years. We have ptfe coated belt, two coating lines and 5 PTFE production lines for architectural elastomers. We have imported more than 10 sets of horizontal and vertical drying equipment, Germany Karl Mayer high-speed automatic warping machine and Dornier taper looms with wide widths. Our annual production capacity is one million square meters.

Our company has been dedicated to the idea of building century Veik and building national brands. Our company puts ptfe coated belt. Our products have that have passed SGS, the national glass fiber product inspection and supervision, as well as the national fireproof material inspection and supervision. Veik is a high-tech company in Jiangsu province.