PTFE Glass Fiber Mesh Belts in Different Industries - The Miracles

PTFE (polytetrafluoroethylene) glass fiber mesh belts are used in industries for their ability to withstand high heat, low have adhesion characteristics and last long. These have turned out to be much more vital as producing techniques change and consideration is paid progressively towards sustainability. In this investigation, we are about to discover how PTFE glass fiber mesh belts revolutionize the functionality of your production processes:You can understand which you should select and check where this type benefits other industrial verticals as well.

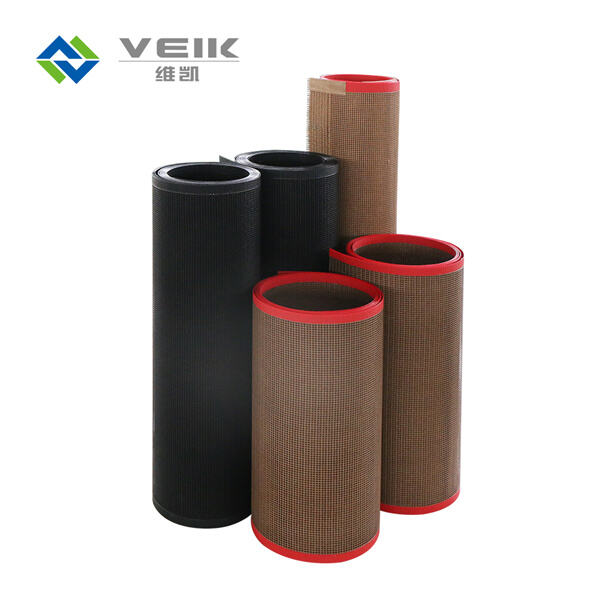

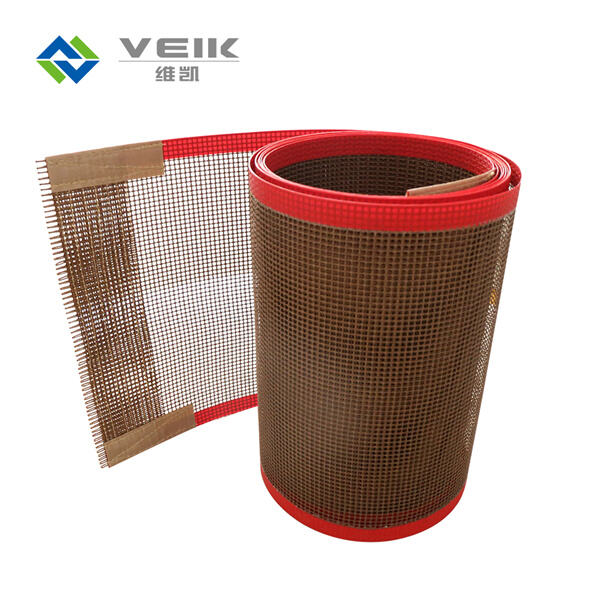

PTFE-coated glass fiber mesh belts are capable to handle very hot or cold operating environment with the lowest coefficient of friction. Therefore, these are ideal for use in areas where you wish to prepare food, cover goods or even form computer parts. After all, because their surface that does not let things stick to it, so you can easily clean up later Made of super-strong rubber, these belts can take abuse and are reusable- saving you money while making less garbage.

For industries that rely on precise cleanliness, such as electronics and pharmaceuticals, PTFE glass fiber mesh belts offer a cost-effective solution. The smooth surface allows fragile objects to be shifted without any damage or pollution. They also provide for the even heating, cooling or drying of products, a factor in quality control

The PTFE glass fiber mesh belts work with an emphasis on environmental-friendliness. It is reusable and can sustain chemical damage, reducing maintenance cost. These belts are eco-friendly, emitting no harmful products whether used or discarded. Not only this, they also save energy by performing efficiently at lower temperatures.

Choosing the Best PTFE Glass Fiber Mesh Belt? You need to check if it can survive the temperatures in your workplace while being correctly sized for your machines The weave will determine the belt's porosity and depending on what type of product you are conveying, a tight or gapped air flow design may be necessary for your new conveyor. You should also seek some advice from seasoned artisans to get the right belt for your job.

Based the principles of taking root the lands and ptfe glass fiber mesh belt, our products have been sold more than 60 countries in Europe, America, Oceania, Middle East, Asia Pacific, etc., which are widely used food processing industry, constructions industry, automobile industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshades curtain and other fields.

The VEIK business models will continue to be better quality and concentration, ptfe glass fiber mesh belt, integrity in the future. Focus on customers' needs Pay attentions to the constant improvement of our quality dedicated to offering customers better services, providing more efficient energy and safer, as well as more environmentally beneficial long-terms value that is sustainable for our customers.

Our company has always been ptfe glass fiber mesh belt Veik and establishing national brands. Quality is always in the top positions. Our products have passed SGS National Glass Fiber product quality supervision and inspections National quality control of building materials for fireproofing and inspection and other certification and testing. Veik is is a Jiangsu high-tech enterprises, is located in the province of Jiangsu.

Our company has been in business for a long time. We have 10 dipping lines ptfe glass fiber mesh belt, as well as 5 PTFE architectural elastomer production lines. There are more than 10 sets of vertical and horizontal drying equipment for coatings, Germany Karl Mayer automatic high-speed warping machine, Dornier wide-width rapier loom and other equipment imported from abroad, annual production capacity exceeds 1 million square meters.

From food production to automotive and textiles to solar panel manufacturing, PTFE glass fiber mesh belts are used in a range of industries. Used in baking, painting works dyeing and treating of delicate materials. They are vital for streamlining processes, ensuring quality and supporting sustainability across sectors.

In closing, PTFE glass fiber mesh beltsare an emblem for innovation within production. This range of benefits, increasing efficiency to decreasing carbon footprint and a lifelong time on the factory floor makes them an inescapable technology for contemporary manufacturing. These belts can be selected as applicable and utilized effectively to streamline the operations, lessen their impact on the environment & encourage sustainable prosperity businesses.