PTFE ( polytetrafluoroethylene ) glass mesh is a kind of creative material that offers best quality properties across an extensive scope of productions. That, PTFE non-stick and chemical resistant properties combined with the power of glass fiber mesh was created between these two components; Composites are suitable for applications that require durability, heat resistance & high filtration efficacy. With this article, we will take you into the world of PTFE glass mesh cloth and explore its unique features as well as how it affects different industries.

PTFE glass mesh cloth is both extremely non-stick and resilient, giving it unique properties that have found a wide range of applications in demanding industries. Because PTFE is non-reactive, it can withstand the reactions of a large number of chemicals and will not corrode or degrade even under some harsh conditions. In combination with its low friction coefficient and self-lubricating properties it serves as a support for good running behaviour within mechanical. On the other hand, its thermal stability makes it ideal for withstanding extreme temperatures- from freezing cold to scorching heat - and endows this material with a value proposition in applications where the temperature range can wildly differ. These hydrophobic and oleophobic properties make surfaces stay clean and dry, things that are becoming more important for many moisture-sensitive environments.

PTFE-coated glass mesh cloths have also reached a new level of performance in the realm of filtration. This structure, when impregnated with PTFE serves as a layer to prevent any particles from passing but still allow air flow thanks to its highly microporous nature. The combination delivers the highest filtration efficiency with minimal pressure drop - saving you energy. In addition, PTFE has non-stick properties which can obviously aid to clean mesh when servicing and prolong the life of the filters keeping them operating properly longer.

PTFE glass cloth is used for food processing, pharmaceutical applications, etc. where hygiene and heat resistance both are important. It can effectively prevent sticking and release products, as a result improve productivity with reduced material loss especially in baking or drying operation. It is employed in the chemical processing industry as a lining for hopper, tanks to protect equipment from corrosive materials. Its resistance to high heat and cold temperatures give it the flexibility of insulating wraps in industrial heating as well as cooling systems. In addition, its ability to be bonded with most adhesives allows for easy inclusion in multi-step manufacturing processes.

A longer life service of equipment if it is PTFE glass mesh fabric lined or shielded The material also serves as a protective layer to guard industrial machinery from abrasion, corrosion and chemical damage that will prevent damaging wear on the most crucial components. This obviously reduces downtime for repairs but also significantly lowers the total cost of maintenance. It is the best material to prevent leakage and ensure proper sealing even at various temperatures with its heat-proof nature, therefore can be used in gaskets & seals. PTFE glass mesh cloth works well as a protective shield which adds to the durability and life expectancy of many industrial assets.

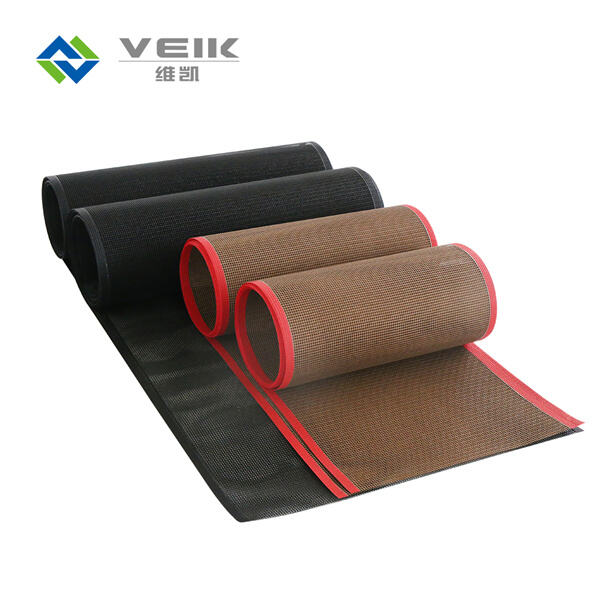

Our company has been in the business for many years. We have ptfe glass mesh cloth, two coating lines and 5 PTFE production lines for architectural elastomers. We have imported more than 10 sets of horizontal and vertical drying equipment, Germany Karl Mayer high-speed automatic warping machine and Dornier taper looms with wide widths. Our annual production capacity is one million square meters.

Based the ptfe glass mesh cloth in land and looking to the global markets, our products have been sold more than 60 countries in Europe, America, Oceania, Middle East, Asia Pacific, etc., which are widely used food processing industry, constructions industry, automobile industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshades curtain and other fields.

Our company has been determined to follow the philosophy of building century Veik and ptfe glass mesh cloth. Our company prioritizes quality over all else. Our products have cleared SGS which is the national inspection of glass fiber products and supervision, and the national fireproof material control and inspection. Veik is a hi-tech enterprise located in Jiangsu province.

The VEIK business model will continue to be better quality and concentration on professionalism, ptfe glass mesh cloth, and concentration for the foreseeable future. Concentrates on the needs of customers Pay attentions to the constant improvement of our own performances, committed to providing customers better services, providing more efficient energy safe, environmentally green long-term value to customers.

In the aerospace and automotive industries, PTFE glass cloth is likely to feature prominently as technology progresses. In aerospace, it helps to reduce weight without sacrificing safety or performance; its ability in acting as insulation for aircraft engines and wiring harnesses is well-known. Its also excellent thermal and electrical insulation properties are key for the function of spacecraft components under difficult conditions in space.

PTFE Glass cloth is also being used more frequently in the automotive industry for high-temperature applications such as engine bays and exhaust systems to help shield heat which can lead to greater vehicle efficiency. Its form of non-flammability and self-extinction make it an excellent resource for enhancing vehicle safety. While its use in battery insulation and as a separator material in fuel cells highlight prospects for it to aide the growth of sustainable transportation solutions enabled by electric vehicles.

So in summary, PTFE glass mesh cloth a great example of material engineering that is creative and flexible. Its versatile advantages; right from advanced filtration to protecting equipment, and special futuristic uses remind us of its importance as a material of choice in so many industries today. And as more studies and uses are found, the future for this versatile composite material appears promising.