Understanding the Versatility of PTFE Fabric in Modern Architecture

It is a type of material known as PTFE fabric (Polytetrafluoroethylene fabric) and it has been becoming increasingly famous among modern architecture. This inimitable fabric offers a plethora of advantages yet, has its limitations as well. But now, we will detail the pros and cons of using PTFE fabrics for new age architectural design!

A PTFE fabric is made of a special polymer with properties that are unrivaled, invented and used versatile in all fields. PTFE fabric is often used in architecture to achieve both natural light and the shade protection from solar radiation, contributing for a pleasant enviroment inside buildings.

Durability: In terms of durability, one of the main benefits to PTFE fabric is consequential. Withstanding extreme temperatures, UV light and chemicals this fabric is the best choice for outdoor structures.

Ease of Care: PTFE fabric is also capable of self-cleaning, which means little maintenance will be required in the long-term.

While the application of PTFE fabric in architectural projects may give a lot of benefits, there are also some disadvantages. Many of the largest drawbacks are that this fabric costs more than other options. As well as this, using PTFE fabric can be intricate and it is an area which require having high level of skill.

Revealing the Structural Capacity of PTFE Fabric in Sustainable Design

One of the more interesting things about PTFE fabric in architecture is that it can be used for eco-friendly design. This material is lighter and more flexible, so PTFE fabric can fully to join the various design concepts. Its other features include recyclability, one of the resins that is best suited for sustainable construction practices with minimal wastage and resource conservation.

Among the unique benefits of PTFE fabric for sustainable design is its ability to contribute natural light into buildings. The implementation of PTFE fabric in architectural components enables designers to develop more sustainable and energy-efficient constructions that rely less on artificial lighting - similar strategies are often ignored or succeed thanks to performative design methods required by codes.

Take a Deeper Look at the PTFE Fabric Molecular Composition and Workings of It

The C in PTFE fabric finds its place largely as a result of the material's molecular structure, which is then used to reinforce those capabilities useful for architectural applications. This is a polymer made of carbon and fluorine atoms that are bonded together, which provides the fabric with its heat resistance as well as chemical resistance. On top of that, PTFE fabric is low in friction and drag coefficient; therefore it can be capable for heavy load without any compromising on stretching or tearing which makes this an ideal material for a structure requiring durable weathering resistance.

The Adaptation of PTFE Fabric For Architectural Uses:

PTFE fabric is an incredibly durable and a versatile material that can be implemented in any number of ways within architectural projects. The unique flexibility and light weight of PTFE fabric makes it suitable for building curved facades, roofing membranes as well outdoor shades or tensile structures to be placed over large opening enclosed spaces.

Expressed Design Freedom and Flexibility in Architectural PTFE Fabric Alterations

PTFE Fabric is an adaptable medium when it comes to the structural design of your building. When it comes down to cutting, sewing or shaping and moulding; PTFE fabric is easily adaptable to different forms providing flexibility for architects when they envision a special design.

Innovative Uses for PTFE Fabric in Contemporary Architecture:

New uses of PTFE fabric in modern architecture have inspired architects to think outside the box with this new-age material. Some examples include:

PTFE Fabric Used For Tensile Structures:Ideal for constructing safe and sturdy structures capable of withstanding all types of inclement weather.

Retractable Roofs - Using PTFE fabric in retractable roofing systems, such as the one at Farifield showground (above), to offer shelter when required and allow natural light or fresh air into spaces.

Insulation: Energy-saving insulation material, which is applied to the roof of a building by PTFE fabric technology, can reduce energy consumption and electricity bills.

ConclusionPTFE Fabric Architecture - Pros & Cons Its durability, flexibility and customisable nature contribute to the growing interest in it within contemporary architectural practice although its cost and need for high level installation expertise are some obstacles. However, the unique molecular structure and compound attributes of PTFE fabric make it a quintessential candidate for allowing creative liberty in modern architectural construction landscapes. The use of PTFE fabric almost certainly has a bright future ahead as architects play with the new material in designs for their projects and that may herald an ocean of inventive structures redefining what can be done on the modern architectural landscape.

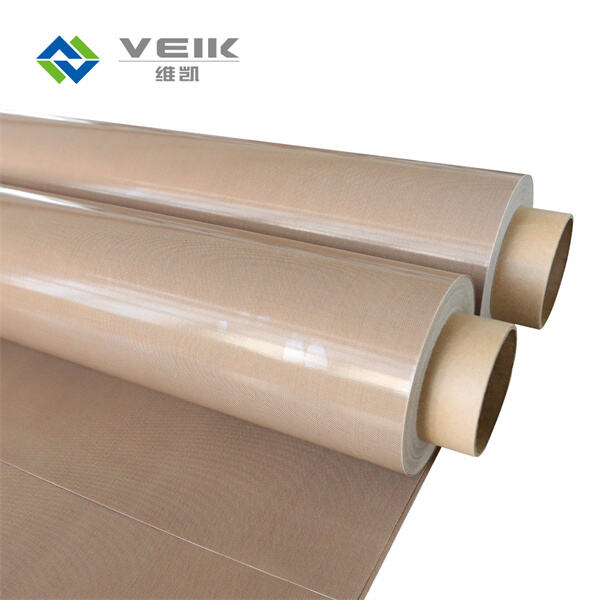

The company's business philosophy will stays better quality and ptfe fabric architecture, professionalism, integrity for the foreseeable future. Be attentive to the needs of the customers Pay attention to the constant improvements of our own performances we are committed to providing our customers better services, providing more efficient energy, safer, more environmentally green long-term values to customers.

Based on the principles of taking roots in the lands and looking to the global markets, our products have been sold to more than 60 countries in Europe, America, ptfe fabric architecture, Middle East, Asia Pacific, etc., which are widely used in foods processing industry, constructions industry, automobile industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshades curtain and other fields.

Our company has been in business for a long time. We have 10 dipping lines ptfe fabric architecture, as well as 5 PTFE architectural elastomer production lines. There are more than 10 sets of vertical and horizontal drying equipment for coatings, Germany Karl Mayer automatic high-speed warping machine, Dornier wide-width rapier loom and other equipment imported from abroad, annual production capacity exceeds 1 million square meters.

Our company has ptfe fabric architecture of creating national brands and building century Veik. Our company is committed to quality. Our products have cleared SGS, the national inspections of glass fiber products and supervision, as well as the national fireproof materials control and inspection. Veik, a Jiangsu high-tech enterprises is located in the province of Jiangsu.