A longer one is if... I would be happy.

Which is where PTFE coated fiberglass belting comes in; this one of a kind solution that has been taking the industry by storm and changing how things are done. This hot new product is far superior in several ways to materials commonly used! We compile a respect for consuming this product increment as it spread vastly in consumption throughout the world, get to know how you want can enjoy other than accounts detail narratives that set itself apart from available anywhere treats today.

So where does PTFE coated fiberglass belting fall in the hierarchy of materials suitable for such conditions - at rock bottom, or up with very best... flamethrowers on tractors? Paired with an ultra-low friction coefficient and exceptional insulation properties, Belting has proven itself in the food applications. It is a lot more lengthy lasting than the old buts and has an opposition oil, fluid that means it quick to clean too. This applies as well to packaging and printing industries that use materials sensitive to high temperature or sharp object.

PTFE coated fiberglass Beltig is unique in terms that it provides an unmatched longevity; a feature far unequal. By blending PTFE with another material (usually fiberglass), the asbestos was left far behind in terms of mechanical properties and wear resistance, which made it perform even better than the other materials that were commonly used for similar roles. This innovation results in the belting giving way after years without degradation even under high-stressed conditions.

The No1 priority when designing materials for use in industrial processing is always safety and that where PTFE coated fiberglass belting delivers; a fact reflected by its cross industry application range. Designed with the utmost care regarding safety are several belting which makes them most suitable as food grade conveyor belt. Special non porous resin ensures that the surface is highly resistant to bacteria build up, enabling cleaning with standard techniques While its heat proofing capability of 260°C allows it be workable in extreme temperatures without putting employees health at stake.

Our business has always been committed to the principle of creating national brands and building a century Veik. We place quality first. Our products have that Ptfe coated fiberglass belting which is the national inspection of glass fiber products and supervision, and the national fireproof material inspection and supervision. Veik, is a Jiangsu high-tech firm, is located in the province of Jiangsu.

The company's business philosophy will stay better quality and Ptfe coated fiberglass belting, honesty, and focus in the near future. Pay attentions to the needs of our customers Pay attention to the constant improvements of our own standards and commitment to provides customers with top-quality service, create more energy efficient, safer, more environmentally sustainable long-term values for our customers.

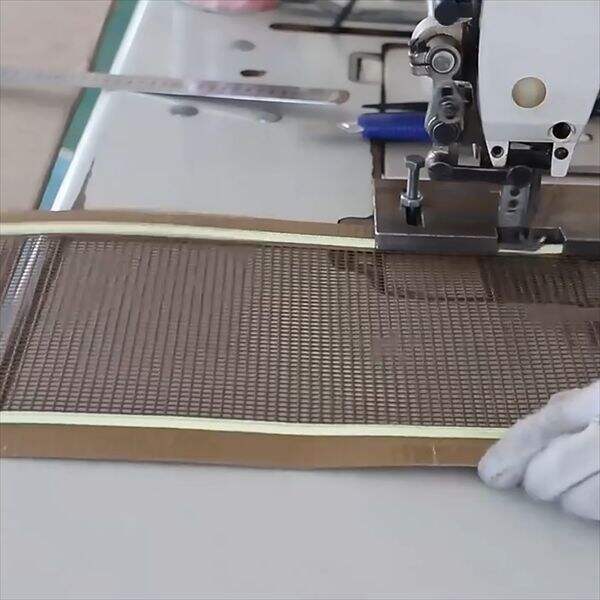

We've had Ptfe coated fiberglass belting and own 10 dip production lines, 2 coating production lines and 5 PTFE production lines for architectural membranes. There are more than 10 sets of horizontal and vertical drying equipment for coatings, Germany Karl Mayer automatic high-speed warping machine Dornier wide-width, rapier looms and other imported equipment, annual production capacity exceeds 1 million square meters.

Based on the principles of taking roots in the land and looking to the global markets, our products have been sold to more than 60 countries in Europe, America, Oceania, Ptfe coated fiberglass belting, Asia Pacific, etc., which are widely used in food processing industry, constructions industry, automobile industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshade curtains and other fields.

All industrial belts are very simple to install, even for a belt having PTFE coated fiberglass. Additionally, this modular conveyor belt can be adapted to suit individual product and project requirements as it is able to operate across a variety of conveyors utilised in the food production chain or common with commercial printing workflows. Its user customer care focused so as required we can too much faster customize it, suits to multiple industries.

PTFE Coated Fiberglass Belting -The Way It Works

The technique is based in fundamental design, functioning as PTFE coated fiberglass belting. It fits seamlessly with conventional conveyors and can be retrofitted to fit your current setup. Doing everything you can with temperature and pressure settings is how they achieve this type of longevity. A regular combination of mild soap and water cleaning should keep most allergens in check but best hygiene practices must still be maintained to prevent that.

Features & Functions of PTFE Coated Fiberglass Belting

One of the best ways to experience its strength and durability is epoch Yogurt top PTFE coated fiberglass belting. This all reflects how in which it has been constructed using PTFE & Fiberglass blend to make most rugged chemical material great for roughest of the conditions. Its robust nature has led it to be deployed in a number of industries where conditions are harsh and conducive to corrosion. Furthermore, non-toxic nature of Teflon consequently finds imbued his position in food related consumables that require high level cleanliness and efficiency.