PTFE open mesh belts are also called Teflon conveyor belt which is widely used in industrial packaging applications. These teflon mesh belt provide many benefits that can improve the performance and efficiency in a number of sectors. Further deep dive in the attributes which makes PTFE open mesh belts an indispensable part of industrial settings.

PFTE open mesh belts are a real leader in food processing applications. Being resistant to temperatures, and not producing toxic fumes at a temperature product rated in excess of 600 degrees C it is the belt of choice for many applications. These components utilize high temperature resistant to corrosion materials that are able to retain their structural integrity even at elevated temperatures, keeping the system safe and reliable. Further, these belts heat and cook uniformly also have outstanding non-stick capabilities which help ensuring high product quality due to preventing burn effect or scarce cooking. While in cleaning is simple and quick, VEIK ptfe mesh belt also helps the flow of production with less downtime for clean-up and lesser chances of cross-contamination that again contributes to an increase in efficiency as well safety at food processing sites.

The PTFE open mesh belts are not only used in the food processing industry but across many others - from textile printing to electronics and packaging. Utilised in everything from the accurate transfer of ink to fabric, validating that heat travels perfectly throughout electronic components and allowing fast yet completely clean-edge sealing within the packaging industry. Beyond sulfur also offer thermal and electrical insulation, making them a "Go-To" polymer for applications that involve chemical fragility. The versatility of ptfe coated open mesh fabric conveyor belt highlight the importance they have in a wide range of industrial processes, proving their ability to be sealed and applied across industries.

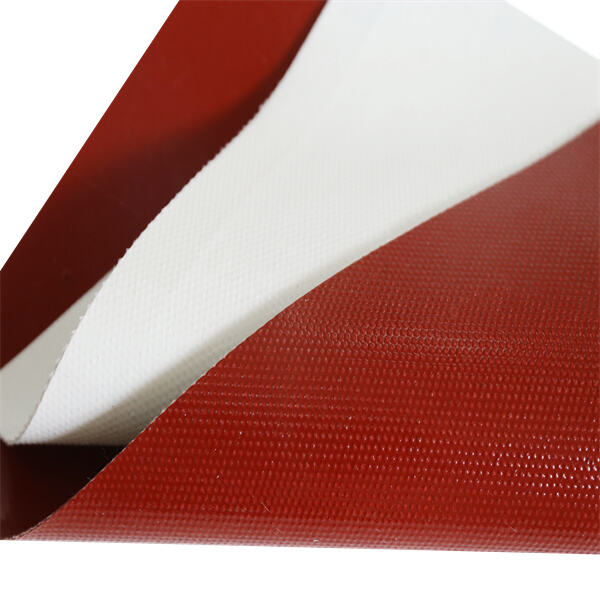

However, the selection of VEIK PTFE Coated Fiberglass Open Mesh Food Conveyor Belt is not as easy considering a number if points would keep in mind for best output performance. Operating temperature range, weight considerations and size requirements along with any additional customizations may all play a crucial role in determining the most appropriate belt. In addition, the operating environment of a belt and its exposure to chemicals must be considered when being used in fast-paced conditions for unimpeded functionality.

Most PTFE open mesh belts are non-stick and have a long life to stand the test of time - adding up for an affordable solution that is durable. As a result, the high release characteristic of Open Mesh Conveyor Belt means that remedial cleaning is easier and their conveyor belts have in-built long life properties. Moreover, their low friction coefficient helps save energy resulting in longer life of equipments and improved plant efficiency. With an effective maintenance program, these belts are as important for the production process and equipment integrity.

The company's business philosophy will stay better quality and Ptfe open mesh belting, honesty, and focus in the near future. Pay attentions to the needs of our customers Pay attention to the constant improvements of our own standards and commitment to provides customers with top-quality service, create more energy efficient, safer, more environmentally sustainable long-term values for our customers.

Our business has always been committed to the principle of creating national brands and building a century Veik. We place quality first. Our products have that Ptfe open mesh belting which is the national inspection of glass fiber products and supervision, and the national fireproof material inspection and supervision. Veik, is a Jiangsu high-tech firm, is located in the province of Jiangsu.

Based on the principles of taking roots in the land and looking to the global market, our products have been sold to more than 60 countries in Europe, America, Oceania, Middle East, Asia Pacific, etc., which are Ptfe open mesh belting, construction industry, automobiles industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshades curtain and other fields.

We've had Ptfe open mesh belting and own 10 dip production lines, 2 coating production lines and 5 PTFE production lines for architectural membranes. There are more than 10 sets of horizontal and vertical drying equipment for coatings, Germany Karl Mayer automatic high-speed warping machine Dornier wide-width, rapier looms and other imported equipment, annual production capacity exceeds 1 million square meters.

PTFE open mesh belts are known as the indispensable part of conveyor technology that is deployed in a wide variety of industrial sectors. Because their non-stick coatings, along with low viscosity and high heat resistance play critical roles to improving productivity, safety and sustainability in industrial operations. The VEIK PTFE Open Mesh Fabric belts, in turn, have myriad benefits to offer and these greens are the enablers of such increased efficiency and safety characteristic for industrial settings - hence we can call them progress an or excellence catalysts.