If you are dealing with some high-temperature applications, the best solution is teflon electrical tape.

Electrical tapes are very important in modern electronics and engineering. They protect wires and cables to improve insulation while creating a barrier against moisture and dust. Of course, not all electrical tapes are equal (no pun intended), and some do a better job at their specific task than others. This is where Teflon electrical tape comes in; a super thin, high-performance tape that all the pros use because it can withstand extremes of heat and has awesome insulation properties.

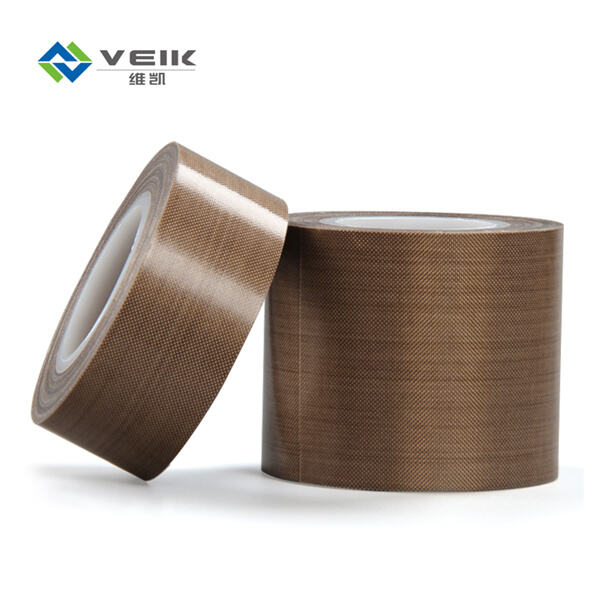

What makes Teflon electrical tape special is it can take the heat and not tear or melt. Comprising a rare material-Polytetrafluoroethylene, or PTFE tape (Teflon is its well-known brand name)-this product excels in chemical resistance and non-stick properties due to no-friction surface.

Teflon tape, often used as electrical heat undertaken can withstand temperatures of up to 260°C providing a solution for any applications that requires high-temperature resistance such as heaters, boilers furnaces and ovens etc. It can withstand almost any condition because of its ruggedness and high-temperature resistance, keeping wires and cables from getting damaged which may lead to catastrophic results.

Why Teflon Electrical Tape is the Best Insulating Solution for Electronics

Besides its thermal performance, Teflon electrical tape is great insulator for an electric wire. A superior insulating barrier to electric currents this is important because in such a way it can prevent short circuits and fires. Non-conductive, tape will not transfer electrical energy from one conductive surface to another which helps guard against accidents.

By covering cables and wires with a thin, even layer of PTFE, Teflon electrical tape helps protect sensitive electric parts from being accidentally smashed while also taping smooth insulation surfaces. Its unsurpassed electrical insulating qualities render it one of the best options for use with sensitive electronics applications.

In the world of automotive wiring, you need a tape that can put up with just about anything - high heat and vibration included. Teflon electrician tape works out to be the most appropriate choice for aforesaid needs. That makes it able to withstand the scorching heat under the hood and constant vibrations a car endures on the tarmac. Additionally, moisture resistant properties protect wire connections from elemental degradation such as corrosion and oxidation which is especially useful when it comes to automotive wiring.

In addition, teflon electrical tape is easy to use and install The thin and light design makes it easy to wrap around wires and cables, without making them bulky. Another good thing about the patented design is that it prevents such things as moisture, dust particles and other contaminants from getting into he cable which in turn helps avoid problems to both wiring safety and security.

This is one of the main things that sets Teflon electrical tape apart from other types; it can handle higher temperatures than most varieties. But one of the areas where Teflon electrical tape stands out is its ability to resist high temperatures, and while regular electrical tapes can only handle up to 80°C — way too low for some situations — this particular adhesive type will experience no problems with anything up to a very impressive 260°C.

Another benefit is its longevity, as Teflon electrical tape outpaces others when it comes to how long they last. An adhesive so strong it endures the most torturous, hideous conditions and still does not break down over time or lose its ability to stick. This feature is vital in critical applications including aerospace, military and industrial.

Teflon electrical tape is renowned for its versatility. It is used in several industries and applications like sealing, splicing, insulating etc. The tape is highly resistant to weathering and possesses excellent insulating properties, making it an ideal response for a variety of applications.

For instance, Teflon electrical tape can be used to seal HVAC ductwork and reduce air leaks; which will improve system efficiency. It can also be used in telecommunications setups to splice wires and cables or form non-stick surfaces are when making food industry, belts. Moreover, it is a non-stick surface for heat-seal machines.

Ultimately, the best option for high-heat applications is Teflon electrical tape; it provides insulation that cannot be beat and can withstand temperatures no non-stick alternatives are able to come close. Its flexibility and other unique attributes result in a vast range of applications suited for industries such as aerospace, military, automotive & industrial sectors. Teflon-electrical-tapeslinky title=Whether you are sealing, splicing or insulating wires and cables, Teflon electrical tape is the ultimate solution to save your day.

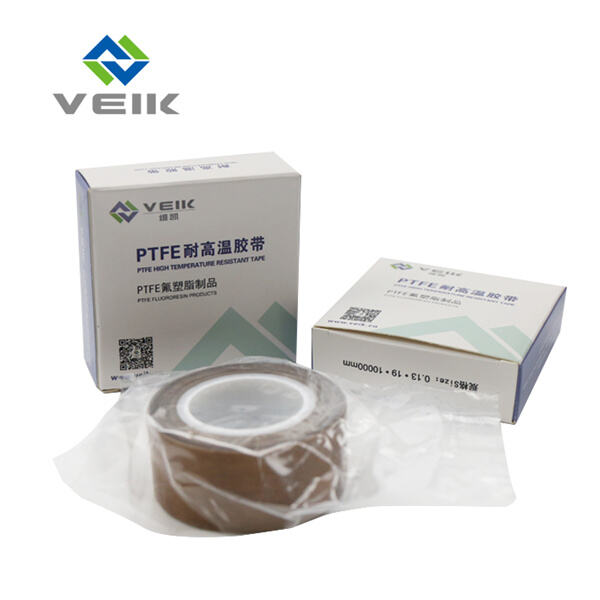

Our company has been in the business for many years. We have teflon electrical tape, two coating lines and 5 PTFE production lines for architectural elastomers. We have imported more than 10 sets of horizontal and vertical drying equipment, Germany Karl Mayer high-speed automatic warping machine and Dornier taper looms with wide widths. Our annual production capacity is one million square meters.

Our company has teflon electrical tape of creating national brands and building century Veik. Our company is committed to quality. Our products have cleared SGS, the national inspections of glass fiber products and supervision, as well as the national fireproof materials control and inspection. Veik, a Jiangsu high-tech enterprises is located in the province of Jiangsu.

Based the principles of taking root the lands and teflon electrical tape, our products have been sold more than 60 countries in Europe, America, Oceania, Middle East, Asia Pacific, etc., which are widely used food processing industry, constructions industry, automobile industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshades curtain and other fields.

The VEIK business model will continue to be better quality and concentration on professionalism, teflon electrical tape, and concentration for the foreseeable future. Concentrates on the needs of customers Pay attentions to the constant improvement of our own performances, committed to providing customers better services, providing more efficient energy safe, environmentally green long-term value to customers.