Teflon Coated Tape - High-Temperature Applications Done the Right Way

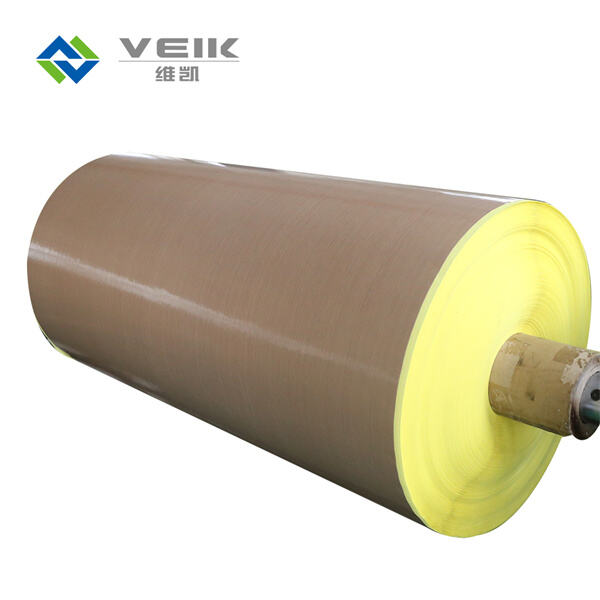

There is no such person who does not like a Teflon coated tape and it is being used in all most all the industries on account of its some extraordinary features, it can withstand high temperature also non-stick reagent resistance etc. It is made from a very versatile and durable product, which in short means they drench fiberglass mats in Polytetrafluoroethylene (PTFE), to give that low friction property and heat endurance. The cloth is then laminated with a high performance silicone adhesive allowing easy on & off removal without leaving any sticky residue.

Reasons why Teflon Coated Tape is Ideal for High Temperature Applications

Teflon coated tape is designed to withstand temperatures as high as -73°C to 260°C (-100°F to 500)°F), so it's perfect for applications that require such kinds of intense heat. Due to its high electrical insulation, chemical resistivity and non-adherence it is a material of choice for the industrial usability wherein there is no other way that can serve better.

Heat Sealing & Packaging: Heat sealing machinery and packaging equipment use teflon coated tape to protect hot wires, thermocouples, heating elements. This does away with the need for troublesome lubricants, helps to keep components apart and ensures a seal without any problems.

Aerospace and Automotive Industry - Teflon coated tapes are known for their non-stick properties as well the property to bear high temperatures, so widely accepted in aerospace and automotive industries. Used for sealing and insulating wire harness, engine components, high temperature pipelines.

Electrical Market: The super insulative backing in the tape itself is incredibly beneficial for electrical applications where it can be used to wrap and protect cables, high temperature wires as well as transformers. It helps precludes cables to stick together that might result in electrical shorts, and thus improves safety.

Food Industry - The non-stick property of teflon coated tape along with its ability to withstand heat makes it a great option for using in the food industry. This safe material is FDA-approved to be used in food packaging, baking and freezing applications.

Printing: In printing industry, Teflon coated tape is used as a non-stick surface to enable machinery to move in and out with ease without scratching the activity load or getting stuck on it.

Teflon coated tape is very useful and it can increase the efficiency of production lines. Its non-stick properties and lubricity enable release and prevent adhesion, promoting faster production throughput of higher quality parts. It also minimizes downtimes by eliminating the necessity for intensive cleaning and maintenance of machinery.

There are many reasons why teflon coated tape is a better choice as compared to other types of adhesive solutions. For a start, its low-friction, non-stick properties make for quick release cutting down on mechanical wear and tear. Second, its high heat resistance makes it ideal for the toughest industrial settings. Third, acting as a great electrical insulator that lowers the chances of an electricity short occurring making it much safer. Moreover, it is safe for use in food packaging/processing industries as it has been approved by the FDA.

How To Pick The Right Teflon Coated Tape For Your Needs

Selecting the appropriate Teflon coated tape for your specific application requirements can enhance its lifespan and peel-and-stick strength. It must take many questions into consideration such as:

Temperature Range: Confirm that the tape will not degrade under temperatures seen in your application.

Strength and Thickness: Weight the necessary strength and thickness required for your specific application.

When it comes to Width and Length, you will always want the tape size that fits your application.

These conclude the reason why teflon coated tape shows ultimate heat resistance, non-stick property with chemical resistance being a versatile material for many different industrial situations. These qualities enhance production efficiency, reduce downtime and improve safety; - It can stand up to spills. This is how you will decipher the best Teflon coated tape that can meet your application requirements deeply when taken into concern the above factors.

The company's business philosophy will stay better quality and concentration professionalism, teflon coated tape, and integrity in the future. Pay attentions to customer requirements to improves our product quality continually and provide exceptional service.

We have a teflon coated tape, and have 10 dip productions lines, 2 coating production lines and 5 PTFE architectural membrane productions lines. There are more than 10 sets of horizontal and vertical drying equipment for coatings, Germany Karl Mayer automatic high-speed warping machines Dornier wide-width, rapier looms and other imported equipment. Annual productions capacity is 1 million square meters.

Based on the principles of taking roots in the land and looking to the global market, our products have been sold to more than 60 countries in Europe, America, Oceania, Middle East, Asia Pacific, etc., which are teflon coated tape, construction industry, automobiles industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshades curtain and other fields.

Our company has always been teflon coated tape Veik and establishing national brands. Quality is always in the top positions. Our products have passed SGS National Glass Fiber product quality supervision and inspections National quality control of building materials for fireproofing and inspection and other certification and testing. Veik is is a Jiangsu high-tech enterprises, is located in the province of Jiangsu.