PTFE seamless belts are very interesting! There are some significant roles they play in different industry, helping to reduce human efforts and improving productivity. We look at the PTFE seamless belts and try to understand why it is important.

The Manufacturing Process and Benefits of PTFE Seamless Belts Surprised The Industry I

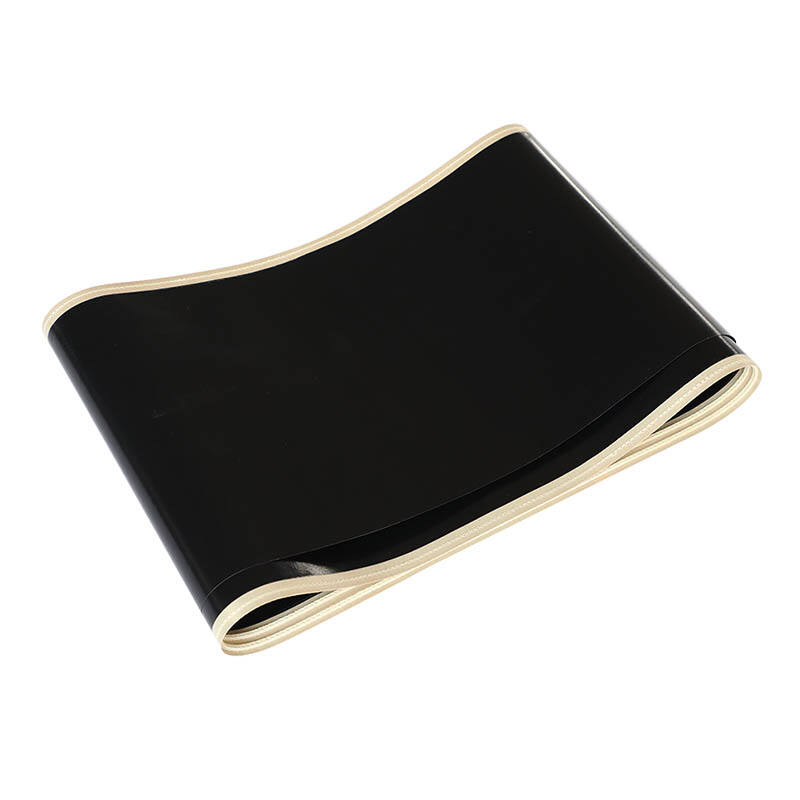

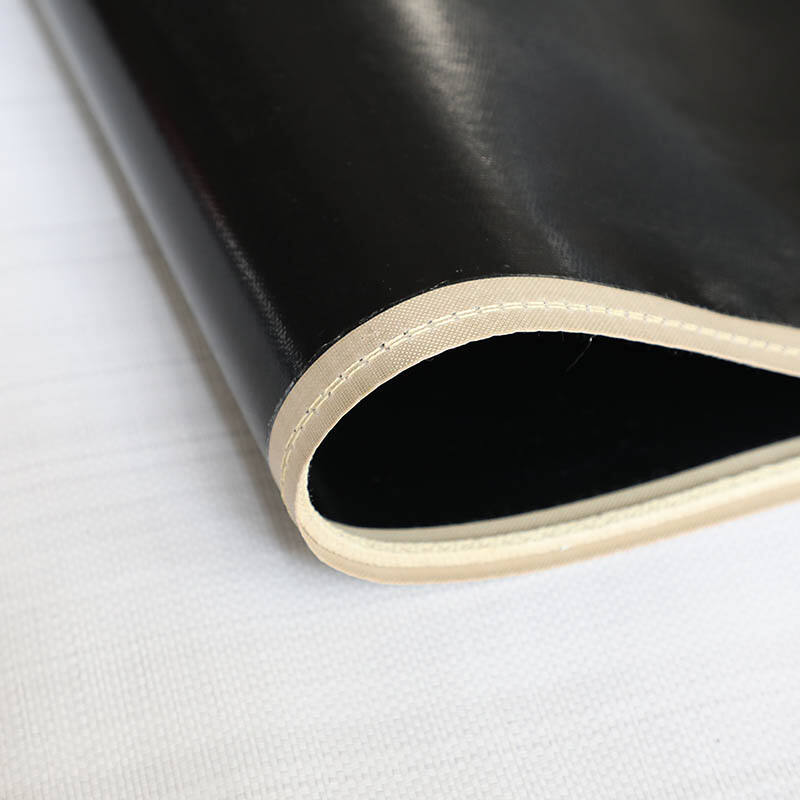

The PTFE seamless belt is made from a phenomenal material, known as polytetrafluoroethylene (PTFE). REINFORCED COUPLED CEDAR STRIPS : The most commonly used material because it so strong and can take the heat, as well as all other materials in this process. The manufacturing process: The PTFE material is essentially melted down and then extruded into long, fragile-looking strings. And, very finely their lies are cleverly woven into a belt as well.

Especially noteworthy is the way in which PTFE seamless belts are exceptionally strong. This allows them to be reused time and again without the fear of getting worn out soon. Further, the non-stick property of PTFE material allows for easy cleaning which is help full in industries requiring a clean work environment such as food and beverage industry.

PTFE seamless belts are used by numerous industries including the food processing and printing. Part of what makes these belts so popular is that they are designed to withstand high temperatures, meaning ovens or other hot areas of operation won't inhibit your process.

PTFE seamless belts also share excellent flexibility. This quality makes them easy to assimilate into a wide variety of machinery and processes. In addition to their flexibility, they can fit in tight spaces when standard belts may have trouble.

Google+ The Many Uses of PTFE Seamless Belts Across Different Industries

The widespread use of PTFE seamless belts in different sectors is a manifestation of the versatility they offer. In the food processing industry, these belts allow for products to easily travel between ovens and other machinery. These systems extend to solutions that serve packaging and labeling machinery.

PTFE seamless belts are invaluable in the printing industry as they enable to convey paper through the printer and press. In addition, they are indispensable in drying and coating applications.

There are also major benefits for the textile industry using PTFE seamless belts. These belts are important components of fabric dyeing and printing, non-woven fabrics manufacturing machines.

The Food Sector and How PTFE Seamless Belts Improve Operational Efficiency

Top of FormBottom of FormExample, in the food industry: PTFE Seamless Belts are crucial to transportation such products as liquids through drying equipment processing examples include seafood, bread and many other types foods. Proper cleaning and maintenance of these belts is vital to get the best performance from the machine.

Proper cleaning the PTFE seamless belt in the food industry is also very important, a mild detergent with warm water can be used to remove any debris otherwise it may lead to bacteria build up. It is also important to make certain the belt remains fully dry prior to being put back into place and properly tensioned as stretched or slipping belts can lead be a source of slower processing speeds resulting in potential damage done to product.

Good maintenance and cleaning helps to protect PTFE seamless belts so that they maintain a longer life span with consistent high performance. The following are among the most important techniques of maintaining these Belts and straps properly.

The belt should be cleaned regularly with a mild detergent (dish soap) and warm water.

In order to achieve optimal results, it is necessary use the right tension.

When not in use, keep the belt stored in a clean and dry place.

These pointers aid you in keeping your PTFE seamless belt at its best while consistently providing efficient performance.

So there you have it... PTFE seamless belts can be applied in a myriad of industries and on almost any belt driven applications. PTFE seamless belts are good when you work for the food processing industry, textile, and other industries where a high-temperature chemicals resistance belt is needed in general. With regular maintenance and care -the secret to durability- of your chemical resistant PTFE belt, follow the aforementioned strategies and ensure long-lasting functionality.

Based the principles of taking root the land and looking to global markets, our products have been sold more than 60 countries in ptfe seamless belt, America, Oceania, Middle East, Asia Pacific, etc., which are widely used foods processing industry, construction industry, automobiles industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshade curtains and other fields.

Our business has always been ptfe seamless belt and building a century Veik. We places quality in the first place, our products have passed SGS national glass fiber quality inspections and supervision of products National fireproof building materials quality supervision and inspections, as well as other certifications and testing. Veik is a leading high-tech business located in Jiangsu province.

In the future, VEIK will continues to keep the company's business philosophy that is better quality, ptfe seamless belt, professionalism, integrity. Be attentive to the needs of our customers constantly improves our services and offers superior customer services.

Our company has been ptfe seamless belt. We have a total of 10 dipping lines, two coating lines and 5 PTFE architectural elastomer production lines. We have imported over 10 sets of vertical and horizontal drying equipment, Germany Karl Mayer high-speed automatic warping machine and Dornier taper loom with wide width. Our annual production capacity is 1 million square meters.