Benefits of PTFE Coated Fiberglass Tape

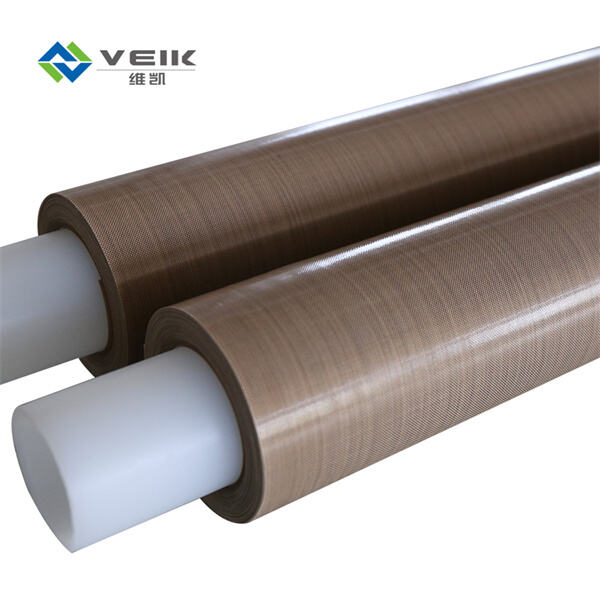

What is PTFE Coated Fiberglass Tape Developed from a woven fiberglass base that has been coated with PTFE, this tape provides an excellent sealing option for areas such as aerospace, utilities and chemical processing.

Wonderful High Temperature Resistant Property - PTFE coated fiberglass tape is one of the many unique things about it. Made a back with a resistance level of # 9 so as to withstand temperatures up to 500 degrees Fahrenehit, this tape kept completely through the heat for over about six weeks. This property also makes it a popular choice for other high-temperature heat insulation applications.

Chemmours Teflon coated tape has an excellent resistance to many chemicals, oils and solvents as do the vast majority of PTFE Fiberglass tapes. It makes it resistant to almost all types of chemical making them an ideal choice in case you own a business which releases chemicals. This durability makes it a reliable option for tough chemical processing situations.

Electrical Insulation Characteristics

PTFE coated fiberglass tape is also known for its ability to serve as an electrical insulator. The insulation has useful applications in that it can prevent leaks or short circuits from occurring. It is a tape that serves to isolate/on interruptions electrical cables, wires or component has resistance against conduction of electric current.

Convenient Application and Usability

In addition, PTFE coated fiberglass tape offers easy application with the possibility to be cut in appropriate length and positioned accurately over surfaces. Its `bendi-bility` allows it to form into complicated designs, making or not Managed Mediaprocessing Platform being used for any task.

Avoiding Leaks and Lower Maintenance Costs

Leaks can be costly in an industrial environment, resulting in lost revenue as well as maintenance costs. PTFE coated fiberglass tape is one of the most essential solutions that provide outstanding anti-leakage properties, keeping airtight seals under high-pressure situations which ultimately helps in minimizing overall maintenance costs. This tape appropriately seals pipe connections, gaskets and flanges to reduce the chances of leaks.

How to choose the best tape for you

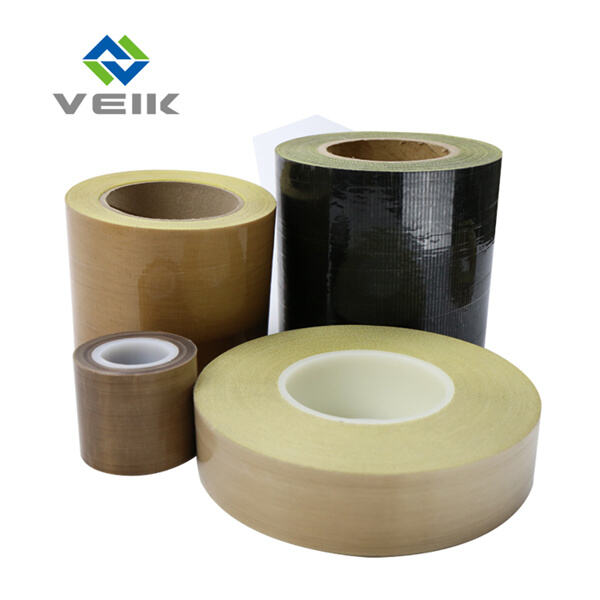

Selecting the right PTFE coated fiberglass tape for an application requires several considerations. There are also different types of tapes available with their varying temperature range, chemical resistance to pressure tolerance and the job it is intended.

Sustainability is a concern with materials going out of style by the way side because they are not nature-friendly but PTFE coated fiberglass tape ropes in as eco - friendly sealing solution and thus remains evergreen. Made of recyclable fiberglass and installed with no hazardous chemicals or solvents, this tape lessens the release of toxic substances into your surrounding area in comparison to alternative sealing materials.

PTFE coated fiberglass tape is widely utilized in aerospace, chemical processing and utilities in real world applications. From insulation of aircraft engines against high-temperature exhaust gases to sealing application in chemical reactors and tanks, this tape proves its worth effectively across a wide array of industrial domains.

All in all, PTFE coated fiberglass tape proves to be a versatile and valuable sealing solution with benefits such as heat resistance, chemical resistant properties, electrical insulation properties low installation costand affordability hereeses environmental friendly nature. This has good practical value in a range of industries and it is clear proof that this can be important part to solve all sealing requirements accurately. It helps to give some much thought on the temperature range, chemical resistance and pressure that are required in PTFE coated fiberglass tape while choosing it for an application as these factors greatly influence how well they perform.

In the future, VEIK will continue to maintain its ptfe coated fiberglass tape, concentration professionalism, and integrity. Concentrates on the needs of customers and continuously improves our quality, and provide superior service.

We've had ptfe coated fiberglass tape and own 10 dip production lines, 2 coating production lines and 5 PTFE production lines for architectural membranes. There are more than 10 sets of horizontal and vertical drying equipment for coatings, Germany Karl Mayer automatic high-speed warping machine Dornier wide-width, rapier looms and other imported equipment, annual production capacity exceeds 1 million square meters.

Based the principles of taking root the land and looking to global markets, our products have been sold more than 60 countries in ptfe coated fiberglass tape, America, Oceania, Middle East, Asia Pacific, etc., which are widely used foods processing industry, construction industry, automobiles industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshade curtains and other fields.

Our company has been determined to follow the philosophy of building century Veik and ptfe coated fiberglass tape. Our company prioritizes quality over all else. Our products have cleared SGS which is the national inspection of glass fiber products and supervision, and the national fireproof material control and inspection. Veik is a hi-tech enterprise located in Jiangsu province.