The use of dryer mesh belts coated with special coatings known as PTFE has changed the way things are dried in most industries. Providing unparalleled performance, dependability and flexibility ensures they are crucial for any industrial drying applications. Constructed from tough materials with a polytetrafluoroethylene (PTFE) coating, these belts boast strength while offering the benefits of high heat resistance and non-stick, chemically inert properties. With the continuous progress of science and technology, coupled with environmental protection issues are becoming more and more prominent in modern society, companies have greater requirements for PTFE coated dryer mesh belts.

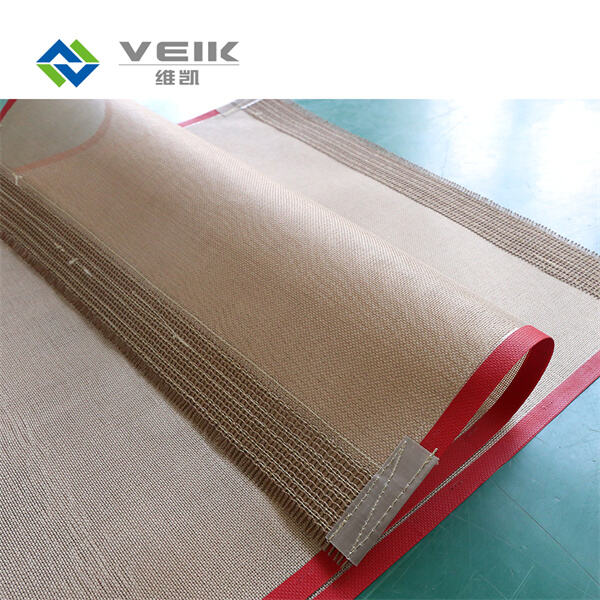

Stopping the materials from sticking to PTFE coated dryer mesh belts is one of their key features. The non-stick nature of this gives continuous operation without the downtimes in case product clongs to belt suface. What's more, low-friction characteristics of PTFE mean reduced wear on the belt (and ultimately less damage to conveyed products). These belts, which are ideal for use in hot drying processes at temperatures of up to 260°C (500°F) without impairmenttheir effectiveness levels as the temperature increasescan maintain a good worklevel of functionality and with unwavering performance consistency even through harsh circumstances.

The power of PTFE is in how these properties come together to form a very unique coating material. This gives it a very high resistance to almost all chemicals (chemical inertness), which will prevent decay and harm caused by corrosion of the underlying mesh. These longevity results in a lot of cost saving on the longer-term, as it eliminates replacement and maintenance needs. PTFE is also FDA approved, which means it is safe for use in food processing environments where hygiene and cleanliness are a must. Moreover, its non-toxic feature provides a more secure working environment through reducing the rate of infection.

PTFE coated dryer mesh belts are in high demand for eco-friendly manufacturing due to the sustainability aspect that has become a major focus of todays world. They last longer after multiple uses than uncoated and other poor quality choices. This not only reduces waste and replacement frequency, but also captures part of the circular economy. Additionally, the specific "no-stick" characteristic of these belts helps to make good use of drying energy in decreasing product adherence and other effortful cleaning upstream that translates into less absorbed power for running its system hence reduced carbon footprint.

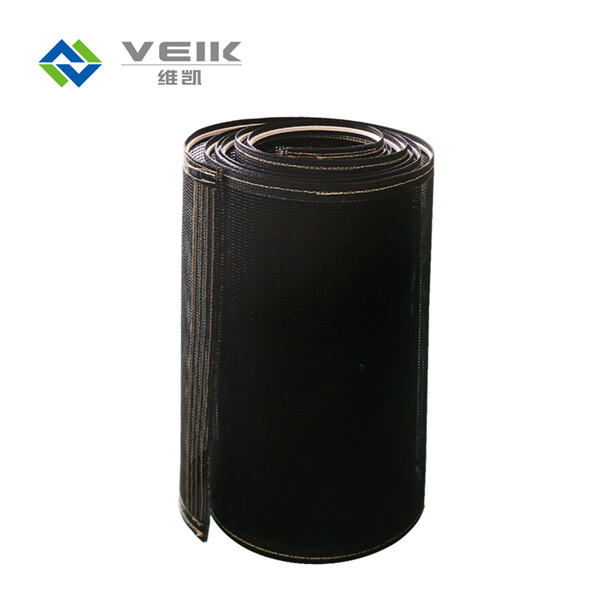

Applying a PTFE coating will also increase the life of dryer mesh belts due to creating a protection against abrasion, heat and exposure to chemicals. Doing regular maintenance such as cleaning regularly, and don't do excessive folding or sharp fold they further maximize their lifetime. If well maintained, these belts can have a life 2 times or more longer than an uncoated belt which means huge savings and improved up time in the long run

In the future, VEIK will continue to maintain its ptfe coated dryer mesh belts, concentration professionalism, and integrity. Concentrates on the needs of customers and continuously improves our quality, and provide superior service.

Our company has been ptfe coated dryer mesh belts Veik and creating national brands. Our company puts quality first. We have our products cleared SGS, the national glass fiber products inspection and supervisions, as well as the national fireproof material controls and inspection. Veik, is a Jiangsu high-tech company is located in the provinces of Jiangsu.

Our firm has been in business for a long time. We have ptfe coated dryer mesh belts, 2 coating lines, as well as 5 PTFE production lines for architectural elastomers. We have imported over 10 sets vertical and horizontal drying equipment, Germany Karl Mayer high-speed automatic warping machine, and Dornier taper looms that have wide widths. Our annual production capacity is one million square meters.

Based the principles of taking root the lands and ptfe coated dryer mesh belts, our products have been sold more than 60 countries in Europe, America, Oceania, Middle East, Asia Pacific, etc., which are widely used food processing industry, constructions industry, automobile industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshades curtain and other fields.

This is proof that PTFE coated dryer mesh belts are versatile, they find their presence across many industries demonstrating the breadth of applications they can cater to. The food industry depends on these belts for baking and drying processes, so that baked goods slip off easily, but can still be produced at very high hygienic standards. This heat resistant and non-sticky properties make it the choice of dyeing or printing operations in textile industries. The chemical resistance and cleanliness also make them particularly attractive in the food industry, or even pharmaceutical companies who use it for medicine production. Where accuracy and contaminant free drying are essential particularly in complex applications like electronics production, PTFE coated belts work best. Their included versatility serves to emphasise how these can be a catch-all service for efficient and dependable drying processes.

To sum up, The PTFE dryer mesh belt is a new technological break-through which integrates both high efficiency and eco-fr... These multi-faceted advantages—from superior non-stick qualities to increased life expectancy and environmental friendliness—make them an attractive solution for those looking to increase productivity, minimize waste and meet the exacting demands of various industries. PTFE coated dryer mesh belts are likely to always be here, and that in no way means we're playing it safe; technology has given us the possibility for a lot of different things.