These special belts are known as PTFE fiberglass conveyor belts which have completely revolutionised the way things were manufactured in factories. These belts are made to resist high temperatures, stick resistant, prove durable and outlast traditional materials. They help improve efficiency, sustainability and product quality on many industries. Well they also deserve a separate post to understand better how these innovative belts are changing the industrial scenario.

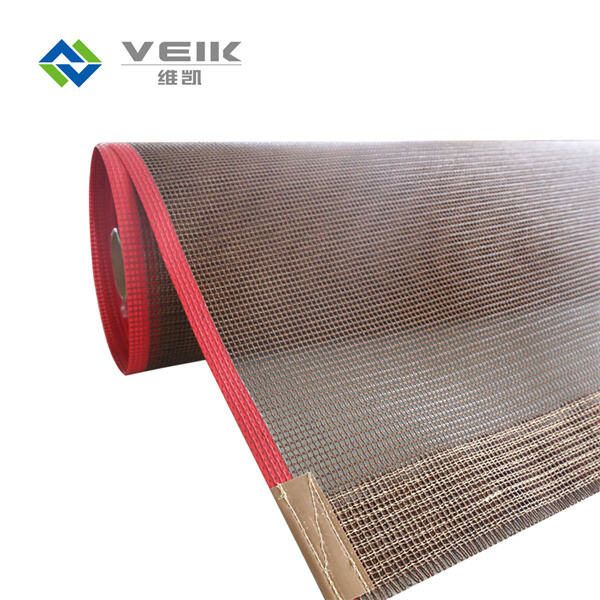

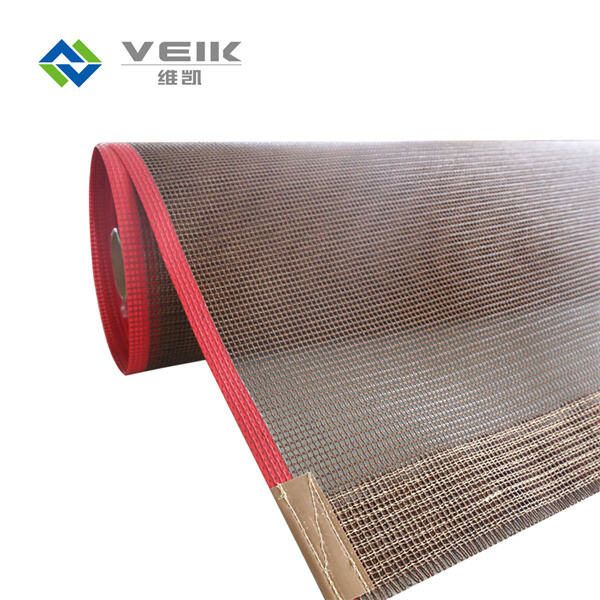

PTFE fiberglass conveyor belts represent a significant step forward in industrial processing technology. Unlike typical metal or rubber belts, PTFE-coated mesh belts are well suited for industrial applications requiring superior resistance against extreme temperatures as well as corrosive chemicals and abrasion. This incredible durability leads to less downtime, lower maintenance costs and ultimately higher production. Belts that can be used in processes such as baking, drying and heat-treating continuously without losing their high temperature resistance features (up to 550°F / 290°C) are a necessity for increased modern industrial efficacy.

The resistance to high temperatures is one of the most prominent aspects concerning PTFE fiberglass conveyor belts. The PTFE surface is non-stick so it does not allow materials to stick and reduces friction which means that the belt stays clean after each use. Moreover, the belt features a high tensile strength fiberglass base that preserves its stability when subjected to heavy loads and repeated stress. The combination of non-stick and tough features plays a special role in industries such as ceramics, electronics or food processing which require high quality consistency. These belts keep last long and the wear figures are reduced drastically if they pass through high-temperature processing.

Given that these are environmentally conscious times and demands in manufacturing, PTFE fiberglass conveyor belt manufacturers have come up with a environmentally sustainable solution. Because of the properties mentioned above, non-stick products wicked waste during production performance since sliding items off leaves no residues. This minimizes material wastage and cleaning solvents, thereby constituting a cleaner manufacturing process. More still, simply put - as these belts last longer less resources will be used in manufacturing or disposal points over time, striking the notes of a circular economy. Hence, the use of PTFE belts is integral to these productive yet environment-friendly advances.

This becomes critical in the face of sectors that require food or rack packing machinery where hygine, clean air and jam free trays are literally a matter of vital importance to quality_STORAGE_DICT. Today, PTFE fiberglass conveyor belts are integral to maintaining these standards. Since PTFE is non-porous, it does not harbor harmful bacteria, which makes the material food compliant as well. In addition to experiencing uniform heat transfer, these belts help maintain the texture, color and flavor of foods which also ensures consistent cooking or drying. It helps avoid adhesion and destroying of fragile products used in packaging, keeping the quality of items. Thus, there are high-quality goods that go hand in hand with the satisfaction of individual customers and therefore PTFE conveyor belts make a significant contribution.

The company's business philosophy will stay better quality and concentration professionalism, PTFE Fiberglass Conveyor Mesh Belt, and integrity in the future. Pay attentions to customer requirements to improves our product quality continually and provide exceptional service.

We have a PTFE Fiberglass Conveyor Mesh Belt, and have 10 dip productions lines, 2 coating production lines and 5 PTFE architectural membrane productions lines. There are more than 10 sets of horizontal and vertical drying equipment for coatings, Germany Karl Mayer automatic high-speed warping machines Dornier wide-width, rapier looms and other imported equipment. Annual productions capacity is 1 million square meters.

Based on the principles of taking roots in the lands and looking to the global markets, our products have been sold to more than 60 countries in Europe, America, PTFE Fiberglass Conveyor Mesh Belt, Middle East, Asia Pacific, etc., which are widely used in foods processing industry, constructions industry, automobile industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshades curtain and other fields.

Our business has always been PTFE Fiberglass Conveyor Mesh Belt and building a century Veik. We places quality in the first place, our products have passed SGS national glass fiber quality inspections and supervision of products National fireproof building materials quality supervision and inspections, as well as other certifications and testing. Veik is a leading high-tech business located in Jiangsu province.

PTFE fiberglass conveyor belts are a clear winner, their use is definitely beneficial and which allows them to have such great properties of adaptability into different manufacturing processes. Custom-engineered to any width, length and mesh configuration, these belts are designed for the most perfect balance each individually application would need. From squeezing down into tight pathways in ovens, to handling significant widths for material conveying applications - these belts can be designed to perfectly suit your needs. Additionally, special coatings or textures can be added to improve release properties and grip for conveying various materials. This amount of customization is to make sure that PTFE fiberglass conveyor belts work perfectly for specific manufacturing environments.

In summary, PTFE fiberglass conveyor mesh belts are a great technical improvement to solve the real questions in front of industry. These belts, from the way they revolutionized high-temperature processes to both their sustainability and product quality benefits, are a prime example of what innovation can bring in manufacturing. The applications and optimizations of PTFE conveyor technology are set to evolve as industries continue their forward march, cementing them in place as irreplaceable devices for achieving efficiency, durability and sustainability with respect to manufacturing processes.