Designers of conveyors in chemical plants usually prefer PTFE coated conveyor belts for their several advantages. Such belts are known for their durability and resistance to chemicals and their capacity to enhance efficiency in the manufacturing procedure. One benefit is that PTFE coated conveyor belts are known for their resistance to chemicals. PTFE is a material used to construct these belts. It is resistant to many chemicals. Therefore, the belt can be exposed to a broad range of corrosive chemicals without being damaged.

Introduction

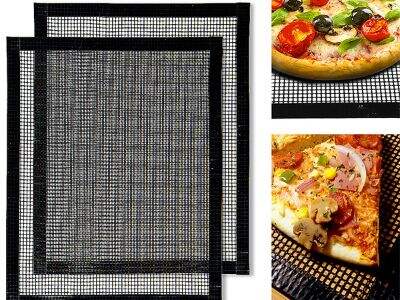

These enable the belt to last longer since less frequent replacements would be necessary. PTFE coated conveyor belts also have a non-stick property. Thus, when materials are conveyed on the belt, there are minimal chances of them getting attached to it. It reduces the possibility of products being contaminated. This quality is very vital especially in the chemical plant where a variety of items is conveyed through that need to be kept discrete to prevent cross-contamination. PTFE wire belts are also heat resistant and can be used in high temperatures. PTFE grilling bags grill can be used in extreme temperatures without the physical properties being altered. Thus the belt continues to provide exceptional performance. The PTFE coated conveyor belts also make the plant more efficient.

About us

Moreover, materials do not stick to PTFE coated conveyor belts, and this minimizes the amount of time taken to clean the belt or maintain it. Operators can run the belt uninterrupted and only need to stop if making other adjustments on the production line such as belt pitching and maintenance. Moreover, PTFE coated conveyor belts are easy to install and replace and only need minimal downtime. All these factors contribute to the efficiency of a chemical plant. In conclusion, the application of PTFE grill mesh bag in chemical plants comes with numerous benefits that enhance production and reduce operational costs.

Benefits

The belts exhibit high chemical resistance, non-stick properties, and can withstand high temperatures, which make them suitable for use in transporting materials in chemical processes. Common Problems Addressed by PTFE Coated Conveyor Belts in Chemical Plants Most chemical plants experience challenges in moving materials from one point to another. For instance, sticky substances and other materials may accumulate on the belt, leading to a reduction in production lines and even damaging other parts. The PTFE belt ensures the materials do not stick on the belt due to its non-stick properties. Furthermore, the operator does not have to clean the belt or maintain it frequently. In addition, PTFE coated conveyor belts are capable of withstanding high temperatures and are resistant to various chemicals, making it suitable to operate in harsh conditions.

Innovation

For chemical plants, where the best PTFE coated conveyor belt to choose, VEIK has all the most suitable for different tasks. Our PTFE coated conveyor belts of high-quality materials. They are long-term and applicable in severe working conditions. The significant advantage of VEIK PTFE coated conveyor belts is the excellent release properties. In these cases, the materials do not stick to the belt, allowing decreasing the fault probability, and enhances the conveyor’s life. The cleaning and maintenance are simple and fast, and the accidentally minimum downtime and low cost for chemical plants.

Conclusion

The correct use of PTFE coated conveyor belt makes the chemical plant more productive. In this case, the materials do not stick to the belt, which means no clogs. Therefore, the material handling procedure is smooth and faff-free, hence coin with high throughput and minimal downtime. Moreover, VEIK’s PTFE bbq bag with stand high temperatures and chemical wear. This enables the chemical plant to depend on our conveyor belts for a decent wage while attaining sixth profit retaining output levels.