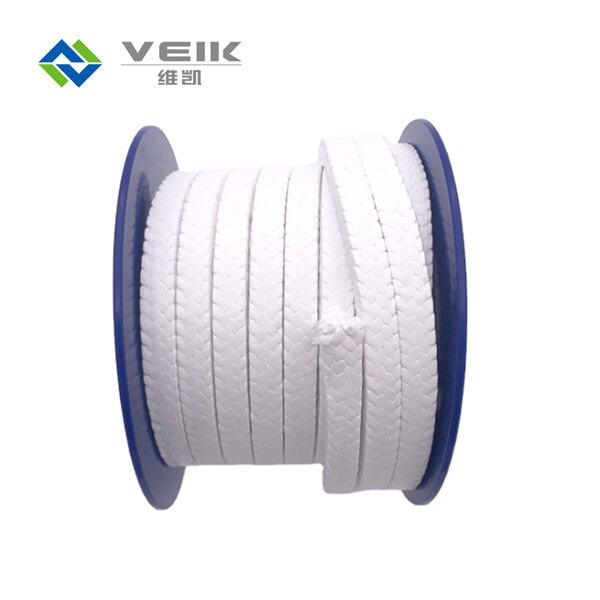

PTFE packing: It is unique of variety material we used in different ways. This makes it ideal for sunny and hot areas where other materials might warp, or fall apart. This unique material is also effective at creating an airtight seal, which in turn prevents leaks from taking place. It can cause problems if things leak and that is why using PTFE packing is a good idea. So, here are some significant reasons to elaborate that how PTFE Packing plays an important role in different areas and situations.

PTFE packing is the perfect material to use when you need your sealant or gasket to function in direct fire and PTFE, due largely do its high melting point characteristics. This makes it good for things that run really hot, such as car engines or equipment in factories. And it requires materials that have the highest melting points. Packing with PTFE literally ensures that the machines are operating as smoothly as possible, which is highly essential. Operationally, if a machine breaks it causes delays and costs allot of money to fix. Well the use of PTFE packing will help keep these issues at bay and everything in tip top shape.

One of the best reasons about PTFE packing is that it will help eliminate leaks. In machines everything should be sealed tight, nothing is allowed to leak out. In places that chemical substance are present for example factories or perhaps laboratories it is even more crucial to have a spillages cleaned upwards correctly, as well of course with public locations where the same hazard can be extremely dangerous. A PTFE packing also ensures a tight seal so you don't have to worry of leaks and, therefore toxins. Use of the PTFE packing will also provide protection to employees, and there won't be any accidents.

Also, when using PTFE packing-it is important to selection the appropriate one for your application. While there are many types of PTFE packing available, each one is specific for different jobs. There are some types that work best in extremely hot environments, and other applications for leaking halt more successfully. Like the right tool for a job, everything works better when you choose well. So making the right PTFE packing selection can not only help your machines and tools do what they should be doing but it might also lead to better results.

PTFE packing can also resist chemical. This makes a perfect product for its ability to keep well when sealed [Think storing in chemicals]. This provides a tight seal to prevent any chemicals from escaping, thereby safeguarding workers and preventing damage. To say the least, PTFE packing cannot corrode and similar materials tend to wear out after a mere short time in tough conditions. That kind of durability is key for hard industrial work, where abuse can be a fact of life.

Less Liquor Wounding: At last, this use of theP TFE Packing can help your machines to last longer than they would. PTFE packing works to prevent leaks and the natural wear that might occur during this time by creating a tight seal. This means your equipment can operate more efficiently and lasts longer-helping you to save time, money. In the event that machines need to be repaired or break down, this is very expensive and it takes a lot of time! PTFE packing is very durable and can withstand being worn down over time, so it will not degrade under wear and tear making this a viable option for use in many different sectors/industry.

We've had ptfe packing and own 10 dip production lines, 2 coating production lines and 5 PTFE production lines for architectural membranes. There are more than 10 sets of horizontal and vertical drying equipment for coatings, Germany Karl Mayer automatic high-speed warping machine Dornier wide-width, rapier looms and other imported equipment, annual production capacity exceeds 1 million square meters.

Based the principles of taking root the lands and ptfe packing, our products have been sold more than 60 countries in Europe, America, Oceania, Middle East, Asia Pacific, etc., which are widely used food processing industry, constructions industry, automobile industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshades curtain and other fields.

Our company has been dedicated to the idea of building century Veik and building national brands. Our company puts ptfe packing. Our products have that have passed SGS, the national glass fiber product inspection and supervision, as well as the national fireproof material inspection and supervision. Veik is a high-tech company in Jiangsu province.

The VEIK business model will continue to be better quality and concentration on professionalism, ptfe packing, and concentration for the foreseeable future. Concentrates on the needs of customers Pay attentions to the constant improvement of our own performances, committed to providing customers better services, providing more efficient energy safe, environmentally green long-term value to customers.