The right heat sealing materials are required when you seal items with heat. Fiberglass coated with Teflon tape is the material that has soared in popularity over recent years. Teflon is a type of non-stick material, which can resist high heat and chemicals so as to be the perfect seal bottom product.

One critical benefit of the use of Teflon coated fiberglass tape is that it does now not permit gadgets to stay and stick all through sealing. Now, the point to consider is that when you are dealing with food packaging then Teflon coating in its sealing material becomes even more important because this will help prevent sticks from contaminants and debris. On top of that, Teflon improves the longevity of the tape since it can stay up to 500° F — making maintenance or replacement less frequent. Everyone should save time and money this way.

Heated sealing can present challenges for the packaging industry because not all products will require the same heat passage. Teflon coated fiberglass tape is being used as the best alternative in packing companies owing to multifunctional and reasonable prices.

Closing Performance - One of the features that make Teflon coated fiberglass tape such a valuable material is its versatility for sealing many different products (dry goods, liquids and powders). Furthermore, this kind of tape works with all types of sealers and machines so that the majority business owners can use it. Moreover, the Teflon coated fiberglass tape is strong enough to seal a variety of packages sizes and weights which makes it highly adaptable to mass production. It also stops packages from adhering to the sealing material, which minimizes chances of contamination or spoilage. This is the reason Teflon(x=1)* PTFE Coated Fiberglass Adhesive Tape has been flourished into Packaging Industry to package Product available in any form and size economically.

Welding in the precision and efficiency needs a good material sealing treatment, its quality will affect the following product. Teflon coated fiberglass tape is now used in welding industry and it can resist high temperature,non-sticking etc features make teflon (ptfe) glass fiber cloth an ideal material for welding applications.

Teflon coated fiberglass tape has a smooth surface making it non-stick, and only regular cleaning is needed to facilitate quick release really allows for excellent production efficiency. It also withstands chemical and UV exposure, which ensures that it has a long service life in comparison to other sealing products. Not only that, but Teflon coated fiberglass tape also has the advantage of being used with a lot more welding equipment than simply hot bar welders - this includes both impulse and ultrasonic machines. This versatility eliminates the necessity for purchasing a number of multiple types, which will save businesses time and money.

Safety and functionality are of the utmost importance in the aerospace industry, which is why top-tier materials that can be counted upon cannot just only useful but also necessary for this market. Best part is our Teflon tape can withstand the extreme temperatures required in this industry all while providing chemical resistance and abrasion resilience.

For Teflon coated fiberglass tape, it is widely used for aerospace application highlighting in fuel tank and pipe sealing. The temperatures range from -200°C up to +250°C and the tape must be able to withstand the highly aggressive chemicals, aviation fuels in these critical processes. Fortunately, teflon coated fiberglass tape is perfect for these types of jobs because it can withstand high and low temperatures without breaking down as well as the constant exposure to chemicals. In addition, Teflon coated fiberglass tape has good stability and duralibilty since it will not corrode, shrink or stretch providing a consistent accurate seal. This makes it the ideal solution for aerospace businesses where safety is of utmost importance and precision paramount.

Nowadays, the food packaging industry is always looking for new seal materials to protect their goods. When it comes to non-stick and a heat resistant tape, the advancement of Teflon coated fiberglass has revolutionized this industry.

We provide the Teflon coated fiberglass tape that is used for food packaging which ensures worry free sealing process, sustainableSealing. From the aeration of beverage to freezing foods, from bakery product sealing to liquid packaging; all such food processing equipments are serving wide range of industries. These produce a hermetic seal on the tabs, so that provideness of contamination is minimized and also ensures excellent protection to improve the integrity of seals without compromising easy-opening due to non-stick properties from Teflon. Apart from that, another pro of Teflon coated fiberglass tape in food packaging is its qualities for being sturdy and cost-efficient. It provides excellent protecting effect with lower cost than other sealing material to keep the product fresh and safe.

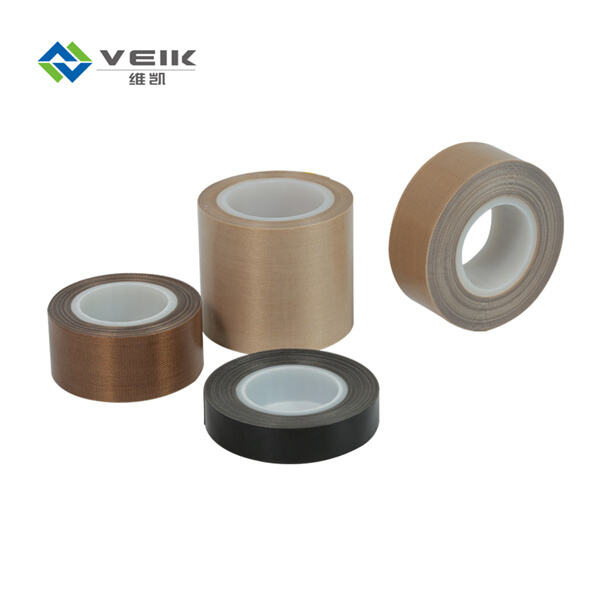

Summing it Up: High Value MaterialTeflon coated fiberglass tape is an extremely versatile and resilient gasket on your hand that you can use to address leaks. Their non-stick nature, durability and resistance to high temperature and chemicals make it the commercial choice for a vast number of different businesses. Application of Teflon Coated Fiberglass Tape in Packaging, Welding, Aerospace and Food Industry

Our company has been determined to follow the philosophy of building century Veik and fiberglass tape coated with teflon. Our company prioritizes quality over all else. Our products have cleared SGS which is the national inspection of glass fiber products and supervision, and the national fireproof material control and inspection. Veik is a hi-tech enterprise located in Jiangsu province.

Based the fiberglass tape coated with teflon in land and looking to the global markets, our products have been sold more than 60 countries in Europe, America, Oceania, Middle East, Asia Pacific, etc., which are widely used food processing industry, constructions industry, automobile industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshades curtain and other fields.

Our company has been in the business for many years. We have 10 dipping lines, two coating lines and fiberglass tape coated with teflon for architectural elastomers. More than 10 sets of vertical and horizontal coating drying equipment, Germany Karl Mayer automatic high-speed warping machine Dornier wide-width rapier and other equipment imported from abroad, annual production capacity is 1 million square meters.

The company's business philosophy will stay better quality and concentration professionalism, fiberglass tape coated with teflon, and integrity in the future. Pay attentions to customer requirements to improves our product quality continually and provide exceptional service.